Mold is quite important for pulp molding manufacturing. Pulp molding manufacturers utilizes molds to shape paper products in the pulp state, making molds a crucial element in the pulp molding manufacturing process.

Disposable paper molded fiber food containers, such as boxes, bowls, and plates, are produced by fibre moulding machines. Since these products have simple shapes and certain versatility, mold design and manufacturing can be relatively straightforward. However, industrial pulp inner packaging and other applications often require larger and more complex products that do not have the same versatility and require custom molds to be designed and manufactured.

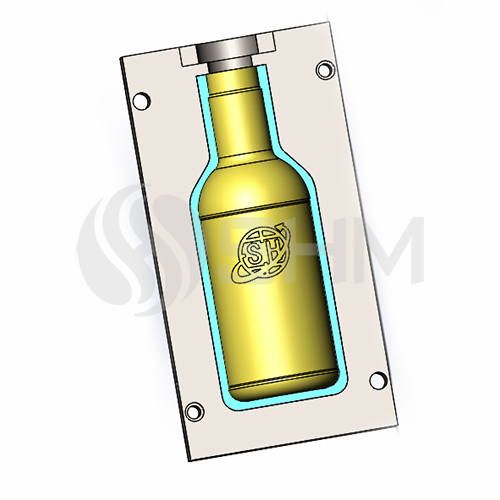

Unlike rubber and plastic products formed in a mold cavity, the slurry used in pulp molding contains only about 1% fiber and requires most of the water to be drained out. As a result, pulp molded product forming molds must be mesh molds.

The forming of moulded fibre products is a continuous process that involves draining a significant amount of water from the slurry. The products are formed to a certain thickness on the mesh mold in a deposition process. Therefore, the paper pulp product must be formed on the surface of a single convex or concave mesh mold. As the thickness increases, the filtering performance decreases, and the thickness forming speed decreases. Therefore, when the pulp product is formed, the wall thickness of each part must be synchronous, ensuring that the wall thickness is consistent everywhere, regardless of the product's complexity.

After the paper pulp packaging is formed, it becomes a wet paper base with a water content of 70-75%. The wet strength of the newly formed wet paper base is very low. Therefore, after the mold is closed by another corresponding convex or concave mold, the wet paper base is placed in the mold cavity, and air pressure is used to transfer it, forming the pulp molded product on a single convex or concave mold. These particularities of pulp molding increase the difficulty of molded pulp product and mold design.

SHM is one of the leading paper pulp packing machine manufacturers & suppliers in China,not only developed different molding dies,but also devote to the design and manufacture of pulp moulding dies, pulp moulding machines, hot pressing equipment and hot press dies. We accept customized pulp molding shape and molded pulp tray, such as full automatic pulp molding production line,sugarcane pulp plate making machine, shoe tray molding machine, apple tray making machine etc.

Just feel free to send us an inquiry here now, let's discuss the fiber solution that fits your brand and product!