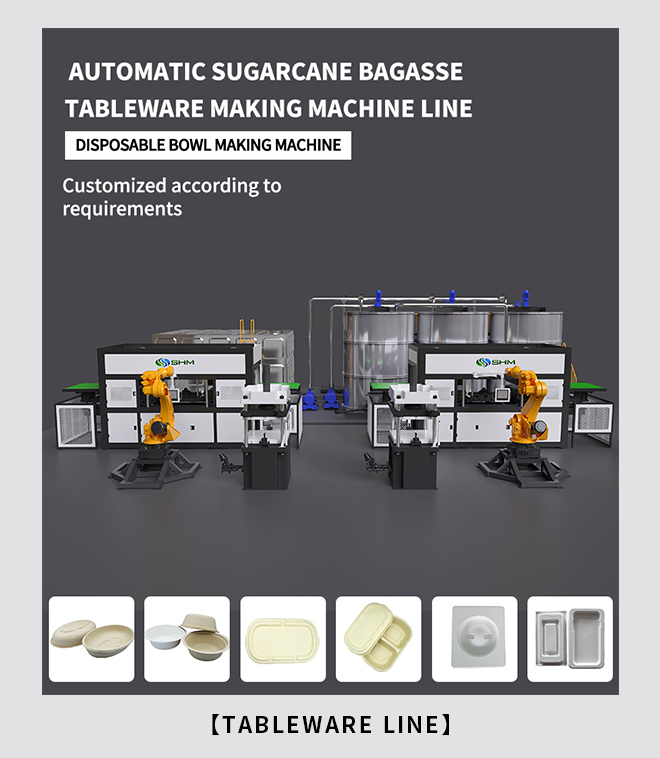

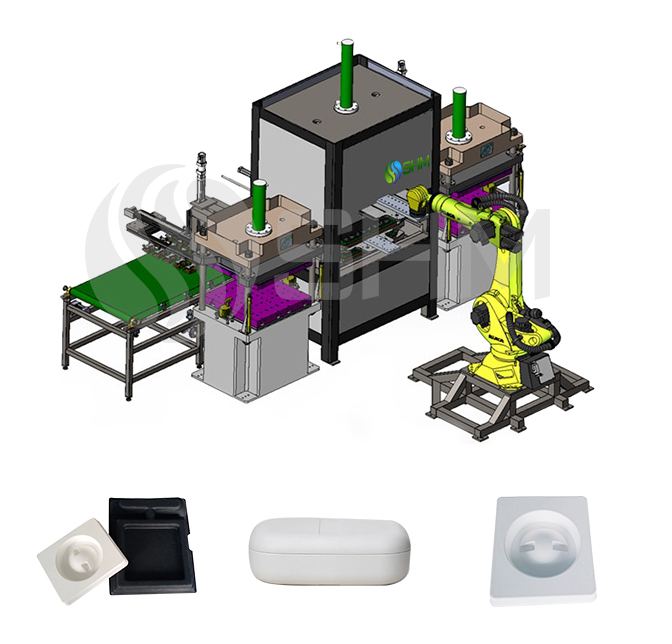

SHM automatic machines for biodegradable plates and tableware offer pulp molded technology and precision engineering to meet the demands of sustainable and eco-friendly tableware production. These biodegradable tableware machinery

are designed to handle various biodegradable virgin fiber, such as sugarcane bagasse pulp, wood pulp, straw pulp, bamboo pulp, ensuring the production of high-quality, environmentally conscious plates and tableware.

Advanced Thermoforming Technology to efficiently shape biodegradable fiber into the desired plate and tableware forms;

Fully-automatic control;

Stable and durable;

Energy saving;

Can produce high-precision free trimming products;

Well use of forming mold, 2 hot-pressing molds share one forming mold, saveing one forming mechanism;

High cost performance intelligent control system;

Safe and simple operation and maintenance;

SHM is a global supplier of high-quality molded fiber packaging production lines, we provide sustainable and innovative solutions for the food service and packaging market.

In 1986, the founder of the company Mr Chao started his work at pulp molding industry, and holds a number of pulp molding patents.

In 2007, SHM was established;

In 2014, SHM participated in the formulation of industry standards for pulp molding in China;

SHM team pay great importance to quality, automatic pulp molding equipment factory direct;

Owns CE and ISO9001 certificates;

13+ years high-tech enterprises in China;

15+ years Alibaba member;

SHM owns 40+patents for fiber molded machines;

Approvals from Top 5 USA packaging companies.

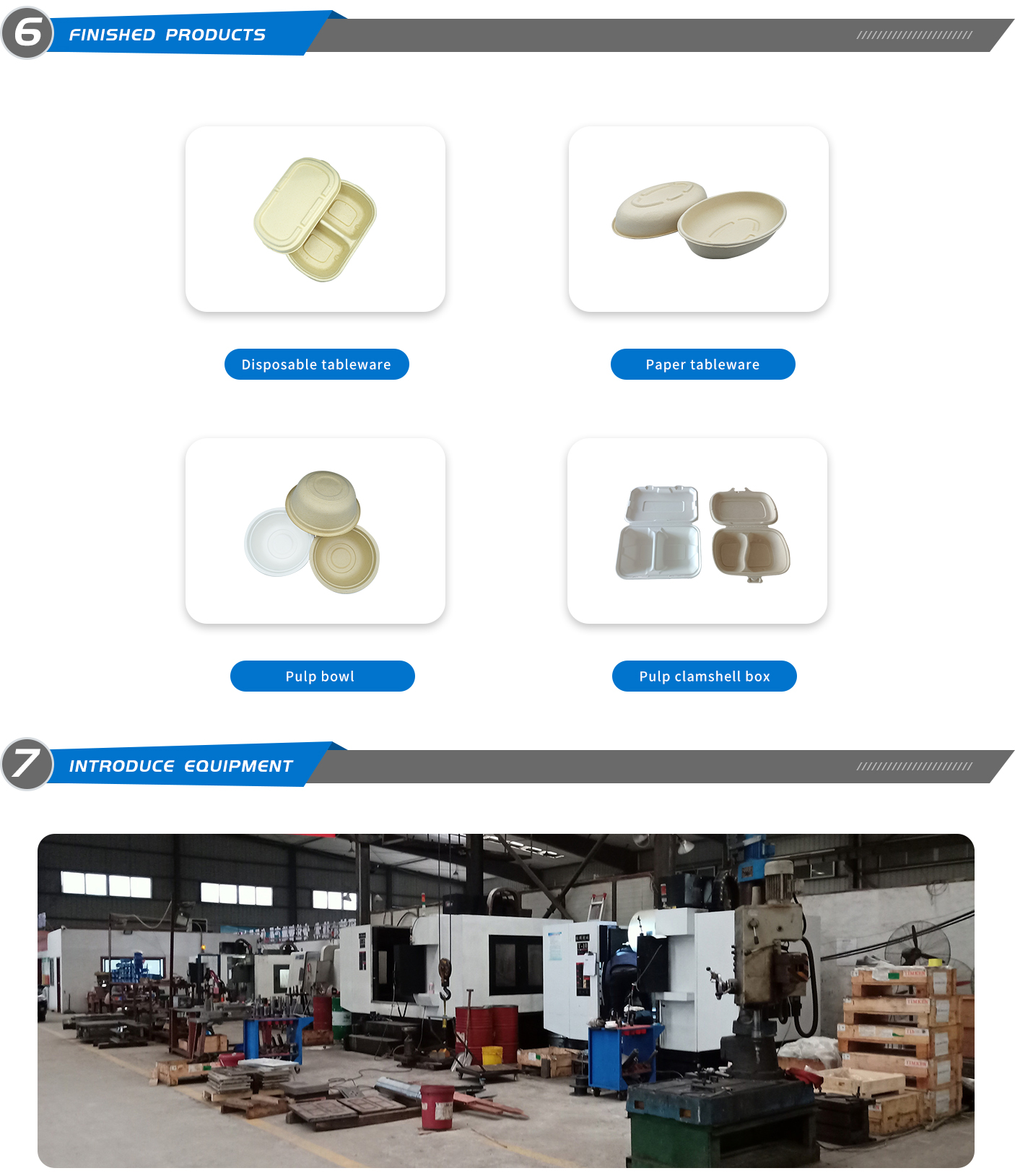

How to biodegradable tableware from virgin paper sheet?

Creating biodegradable tableware from virgin paper sheets involves several steps, and you've already outlined some key processes. Here's a detailed guide:

Materials:

1.Raw Materials:

● Sugarcane bagasse pulp

● Wood pulp

● Straw pulp

● Bamboo pulp

2.Chemicals (Optional, Depending on the Pulp Type):

Bleaching agents (if necessary)

Additives for strength and flexibility

3.Process:

Pulping:

Extract fibers from raw materials through mechanical or chemical pulping.

Sugarcane bagasse often requires less processing due to its fibrous nature.

4.Forming:

Form the pulp into the desired shape using molds. This can be done through various techniques like vacuum forming or pressing.

5.Hot Pressing drying:

Apply heat and pressure to the formed pulp to enhance its strength and durability.

Allow the formed and pressed tableware to dry completely.

6.Trimming:

Trim the edges and any excess material to achieve the final shape and size.

7.Packaging:

Pack the biodegradable tableware in eco-friendly packaging, emphasizing its environmental

Considerations:

Additives:

Depending on the chosen raw material, consider adding natural additives to enhance specific properties of the tableware, such as water resistance or flexibility.

Certifications:

Ensure that the production process complies with relevant certifications for biodegradability and sustainability.

Market Research:

Understand the demand and market preferences for biodegradable tableware. Consider factors such as shape, size, and design.

Be aware of and comply with any regulations related to the production and sale of biodegradable products in your region.

By following these steps and considerations, you can produce biodegradable tableware from virgin paper sheets with a focus on sustainability and environmental friendliness.

SERVICE

1. Engineering research and technical consultation;

2. Manufacture;

3. Project Schedule;

4. Preparation of documents and drawings;

5. Training of maintenance and operation personnel;

6. Guide Assembly line installation;

7. Electrical and mechanical design;

8. System integration;

9. System test and handover;

10. One year of after-sales support;

11. Spare parts are included;

12. Installation within the scope of supply;

13 Operation support for the buyer’s factory;

14. System test after equipment delivery;

15. Documentation of assemble line.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED