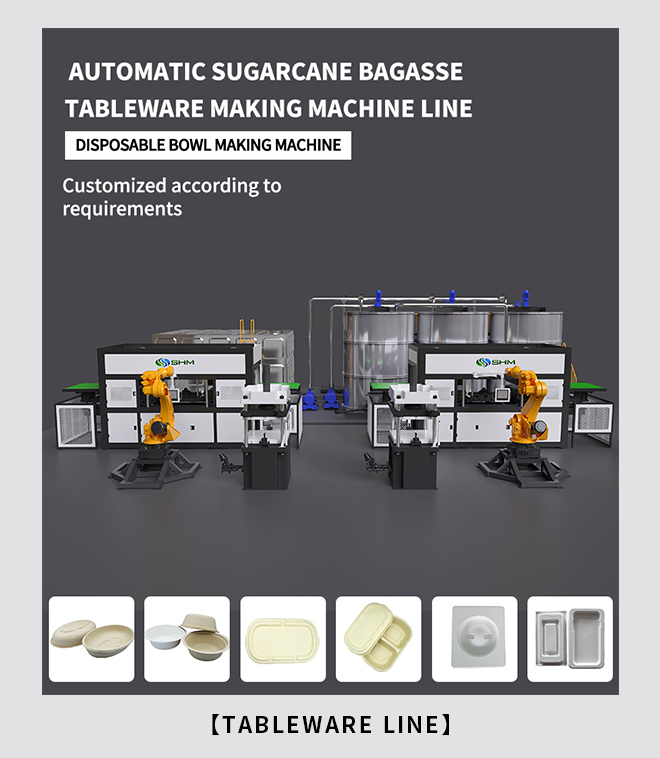

Welcome to SHM, where sustainability meets innovation with our Bagasse Pulp Plate Making Machine. This state-of-the-art equipment is designed to transform bagasse/bamboo/sugarcane/straw/wood etc, the fibrous by-product of sugarcane processing, into high-quality, eco-friendly food containers. SHM's commitment to environmental responsibility and technical expertise is encapsulated in this machine, offering a green solution for the production of biodegradable tableware.

Efficient Pulping System:

SHM's machine boasts an efficient pulping system, breaking down bagasse into a refined pulp. This system ensures a consistent and high-quality base material for plate production.

Versatile Molding System:

The molding system provides versatility, allowing the production of bagasse plates in various sizes and designs. SHM's machine can adapt to the evolving demands of the market.

Advanced Drying Technology:

Utilizing cutting-edge drying technology, our machine ensures the optimal strength and durability of the bagasse plates by efficiently removing moisture during the drying process.

Optional Hot Press System:

For enhanced plate strength and a smooth finish, SHM offers an optional hot press system. This feature further solidifies the molded bagasse plates, providing additional structural integrity.

Automated Operation:

Designed for user-friendly operation, the machine incorporates automation to streamline the production process, reducing manual intervention and enhancing efficiency.

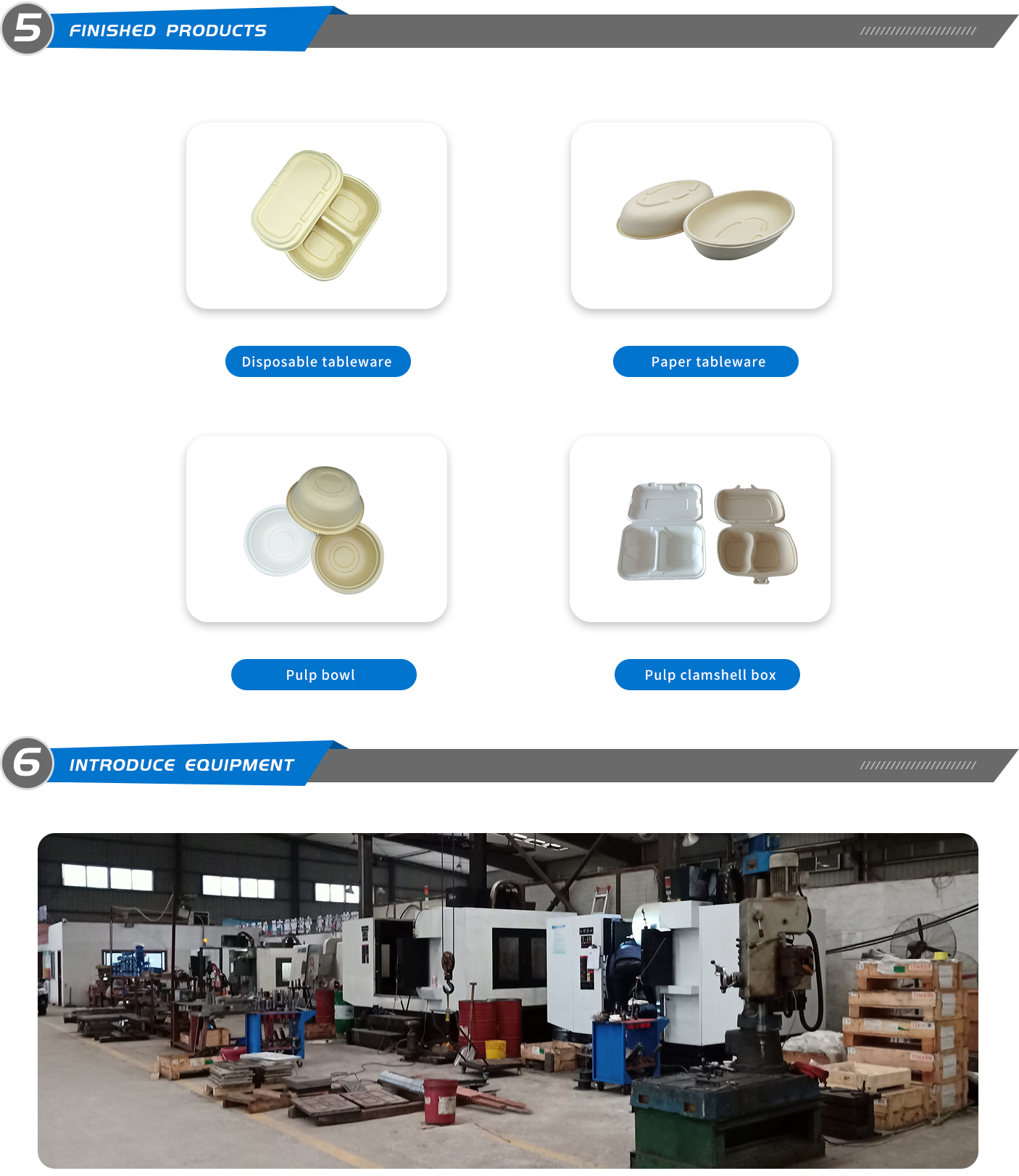

Food and Beverage Industry:

Ideal for serving a wide range of food items, bagasse food containers are perfect for restaurants, catering services, and food events.

Events and Gatherings:

The sturdy and presentable nature of bagasse plates/bowls makes them suitable for events, parties, and gatherings where disposable tableware is needed.

Takeout and Delivery Services:

Bagasse/wood plates are an excellent choice for takeout and delivery services, offering a reliable and eco-friendly option for serving food on-the-go.

Who are we?

We are based in Hunan, China, start from 2007, SHM is a global supplier of high-quality molded fiber packaging tray production lines, we provide sustainable and innovative solutions for the food service and packaging market.

In 1986, the founder of the company Mr Chao started his work at pulp molding industry, under his leadership, the first domestic pulp molding rotary drum egg tray production line was designed. and holds a number of pulp molding patents.

In 2007, SHM was established.

In 2014, SHM participated in the formulation of industry standards for pulp molding in China.

2. How can we guarantee quality?

Automatic pulp molding equipment factory direct,we attach great importance to quality;

Approvals from Top 5 USA packaging companies;

Owns CE and ISO9001 certificates;

Owns 40+patents.

High-tech enterprise for 13+ years

Alibaba member for 15+years

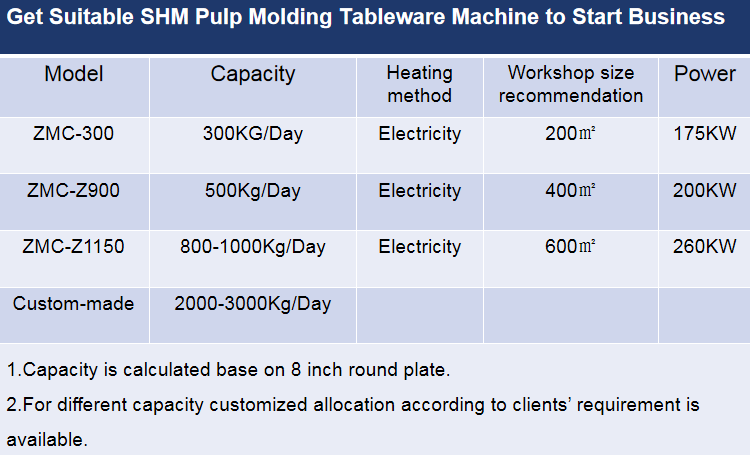

3.What kind of pulp molded machine can you buy from us?

Pulp molding tableware machine;

Bagasse pulp molding machine for industrial package trays;

Egg trays and boxes making machine;

All in one small pulp molding machine for laboratory or sampling;

Nursery Tray Making Machine;

Fruit Tray Making Machine;

Coffee Cup Tray Machine.

SERVICE

1. Engineering research and technical consultation;

2. Manufacture;

3. Project Schedule;

4. Preparation of documents and drawings;

5. Training of maintenance and operation personnel;

6. Guide Assembly line installation;

7. Electrical and mechanical design;

8. System integration;

9. System test and handover;

10. One year of after-sales support;

11. Spare parts are included;

12. Installation within the scope of supply;

13 Operation support for the buyer’s factory;

14. System test after equipment delivery;

15. Documentation of assemble line.

RELATED

RELATED