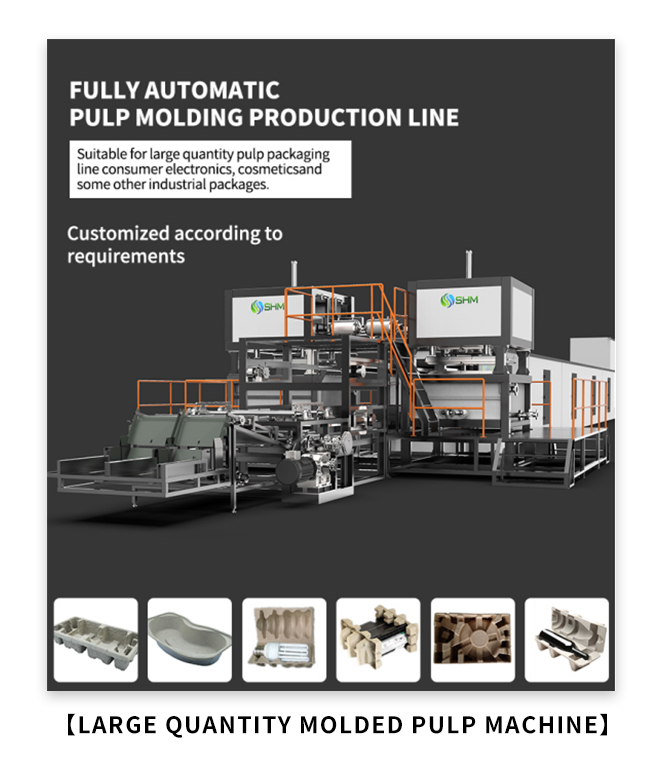

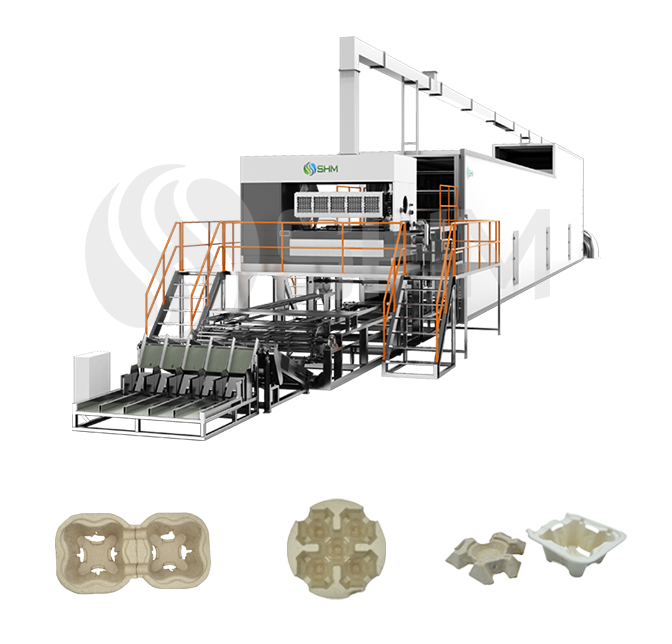

SHM coffee paper cup holder making machine using pulp molding technology is a specialized piece of equipment designed to produce eco-friendly cup holders from recycled waste paper. This cup tray making machine not only caters to the specific needs of the coffee packaging industry but is also versatile enough to manufacture various other paper trays like paper fruit trays, egg trays.

Pulp Molding Technology:

Utilizes advanced pulp molding technology to transform recycled paper pulp into the desired shape for coffee cup holders.

The technology ensures precision, consistency, and efficiency in the forming process.

Metal Drying Line:

Incorporates a muti-layer metal drying line to efficiently and thoroughly dry the molded cup holders. The dryer is designed for durability and facilitates a faster drying process, optimizing production speed.

Raw Material:

Utilizes recycled paper pulp as the primary raw material, contributing to sustainability and eco-friendly production.

The paper cup plate making machine can handle different types of recycled paper, including waste paper from various sources.

Customization:

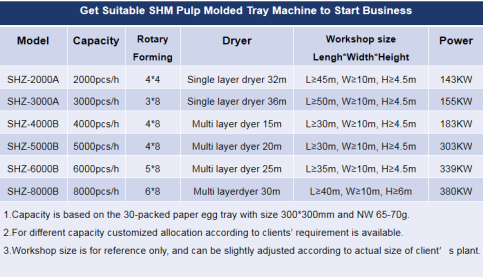

Customization options for cup tray making machines can vary depending on customization options: production capacity, automation level, energy efficiency, mold options etc, meeting specific industry and branding requirements.

Cost-Effective and Efficient:

High capacity disposable cup plate making machine's efficiency, coupled with the use of recycled materials, makes it a cost-effective solution for businesses seeking sustainable alternatives.

SHM coffee cup holder making machine utilizing pulp molding technology with a metal drying line showcases the potential for sustainable and versatile manufacturing. By embracing recycled materials and offering flexibility in product output, this machine addresses the increasing demand for environmentally conscious solutions in the food and beverage packaging industry.

Get a complete solution for cup tray maker from SHM now, we will reply you in 24 hours.

Who are we?

We are based in Hunan, China, start from 2007, SHM is a global supplier of high-quality molded fiber packaging tray production lines, we provide sustainable and innovative solutions for the food service and packaging market.

In 1986, the founder of the company Mr Chao started his work at pulp molding industry, under his leadership, the first domestic pulp molding rotary drum egg tray production line was designed. and holds a number of pulp molding patents.

In 2007, SHM was established.

In 2014, SHM participated in the formulation of industry standards for pulp molding in China.

2. How can we guarantee quality?

Automatic pulp molding equipment factory direct,we attach great importance to quality;

Approvals from Top 5 USA packaging companies;

Owns CE and ISO9001 certificates;

Owns 40+patents.

High-tech enterprise for 13+ years

Alibaba member for 15+years

3.What kind of pulp molded machine can you buy from us?

Pulp molding tableware machine;

Bagasse pulp molding machine for industrial package trays;

Egg trays and boxes making machine;

All in one small pulp molding machine for laboratory or sampling;

Nursery Tray Making Machine;

Fruit Tray Making Machine;

Coffee Cup Tray Machine.

SERVICE

1. Engineering research and technical consultation;

2. Manufacture;

3. Project Schedule;

4. Preparation of documents and drawings;

5. Training of maintenance and operation personnel;

6. Guide Assembly line installation;

7. Electrical and mechanical design;

8. System integration;

9. System test and handover;

10. One year of after-sales support;

11. Spare parts are included;

12. Installation within the scope of supply;

13 Operation support for the buyer’s factory;

14. System test after equipment delivery;

15. Documentation of assemble line.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED