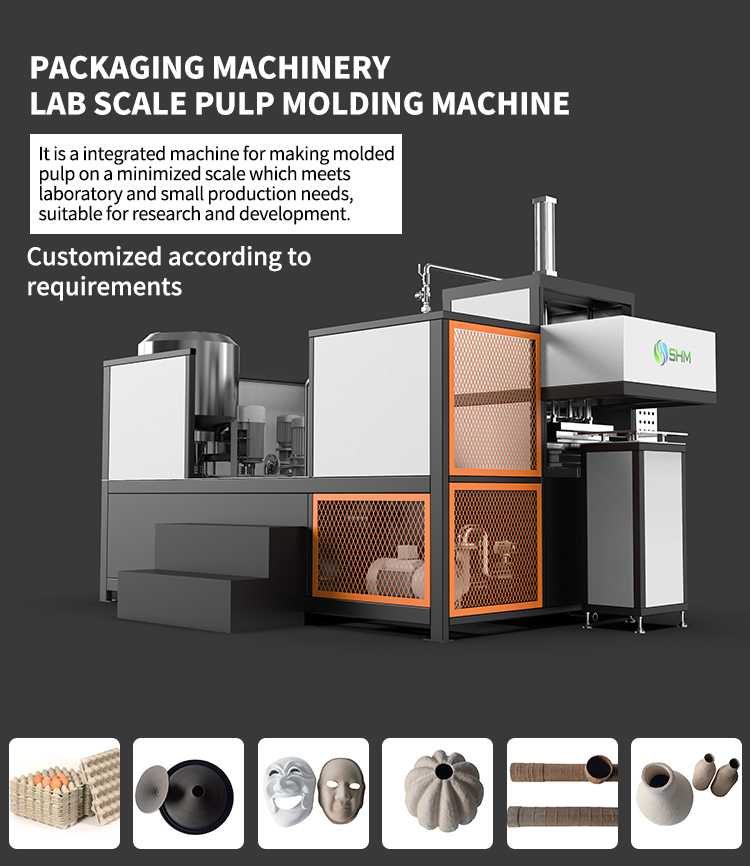

SHM Mini Pulp Molding Integrative Machine, this fiber molded equipment seamlessly combines pulping, molding, hot pressing, vacuum system, and electronic control system.

Compact and versatile, the SHM Mini Pulp Molding Machine is designed to streamline the entire manufacturing process. With integrated functionalities, this disposable pulp molding machinery offers a comprehensive solution for producing molded pulp products. Its efficient design ensures a space-saving footprint, making it suitable for various pulp molded packaging applications.

● Pulping Integration: The machine facilitates a smooth and efficient pulping process, ensuring optimal material preparation.

● Molding Capability: With integrated molding functionality, the equipment shapes pulp into precise and consistent forms, meeting quality standards.

● Hot Pressing Technology: Incorporating hot pressing capabilities, the machine enhances the strength and durability of molded pulp products, ensuring they meet desired specifications.

● Vacuum System: The built-in vacuum system optimizes the molding process, contributing to the overall quality and uniformity of the final products.

● Electronic Control System: The electronic control system provides easy and precise operation, allowing users to manage the manufacturing process with efficiency and accuracy.

● Compact Design: The mini size of the machine makes it an ideal choice for limited space environments, offering flexibility in placement within production facilities.

● Sturdy Construction: Crafted from robust stainless steel, the machine is durable and resistant to wear, ensuring a long lifespan and reliable performance.

● Cost-Effective: The integrated design, coupled with energy-efficient features, makes this machine a cost-effective solution for pulp molding applications.

● Versatility for Laboratory Proofing: Suitable for small-scale production and laboratory proofing, the SHM small disposable pulp molding machinery is adaptable to various research and production needs.

SHM Mini Pulp Molding Integrative Machine combines convenience, efficiency, and versatility, making it an excellent choice for small-scale pulp molding applications and laboratory settings, also good business ideas with small investment 2024.

SHW-360-1:

Size: 3200*1800*2700mm, equipment area 6m².

Efficiency: 1-6times/minutes

Platen size: 550*450mm

Product sample: 132*222mm food tray, 4 pcs/mold

SHW-360-2:

Size :4100*2100*2700mm, equipment area 9m²

Efficiency: 1-6times/minutes

Platen size: 550*450mm

Product sample: 132*222mm food tray, 4 pcs/mold

SHW-360-3

Custom all in one pulp molding machine with all the process including hot-press function.

SHW-720:

Size:7100*2800*2980mm,equipment area 21.3m²

Efficiency:1-6times/minutes

Platen size:1200*800mm

Product sample:132*222mm food tray, could be 14 pcs/mold

SHM is a global supplier of high-quality fibre moulding machines, we provide sustainable and innovative solutions for the food service and packaging market.

In 1986, the founder of the company Mr Chao started his work at pulp molding industry, and holds a number of pulp molding patents.

In 2007, SHM was established;

In 2014, SHM participated in the formulation of industry standards for pulp molding in China;

SHM team pay great importance to quality, automatic pulp molding equipment factory direct;

Owns CE and ISO9001 certificates;

13+ years high-tech enterprises in China;

15+ years Alibaba member;

SHM owns 40+patents for fiber molded machines;

Approvals from Top 5 USA packaging companies.

SERVICE

1. Engineering research and technical consultation;

2. Manufacture;

3. Project Schedule;

4. Preparation of documents and drawings;

5. Training of maintenance and operation personnel;

6. Guide Assembly line installation;

7. Electrical and mechanical design;

8. System integration;

9. System test and handover;

10. One year of after-sales support;

11. Spare parts are included;

12. Installation within the scope of supply;

13 Operation support for the buyer’s factory;

14. System test after equipment delivery;

15. Documentation of assemble line.