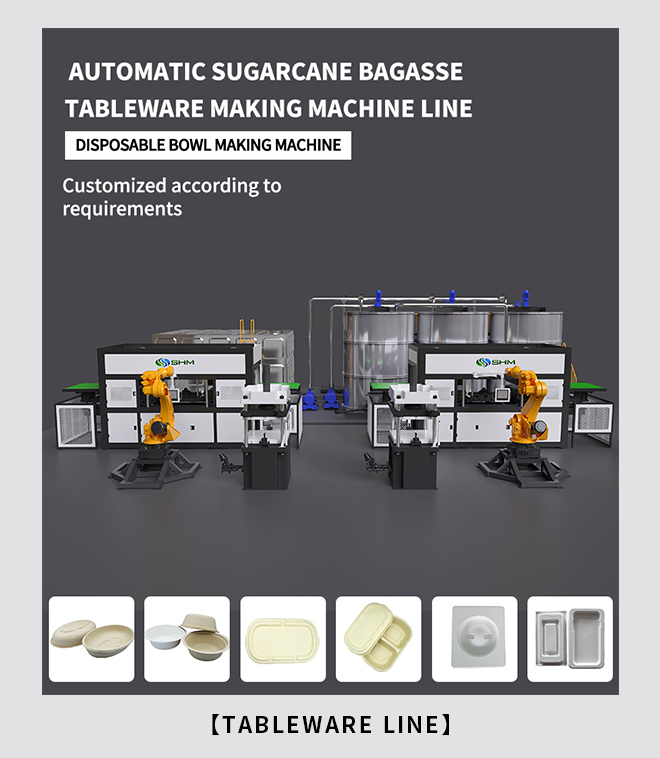

SHM is one of the leading molded pulp packaging machines supplier in China ,it has devoted to the design and manufacture of molded pulp machine production line, pulp moulding machines, hot pressing equipment and hot press molds . We accept customized pulp molding shape and molded pulp tray, such as paper bowl making machine, disposable dinnerware pulp molding machine,pulp molding machine production line etc.

Molded pulp is a sustainable packaging solution and is produced from recycled materials,

Molded pulp packaging machines are used by various industries such as food & beverage, electrical & electronics etc. as they can produce packaging products very cost-efficiently and helps in reducing the carbon footprints of the company. In addition, the rising concerns due to single-use plastic have also increased the demand for the molded pulp packaging machines.

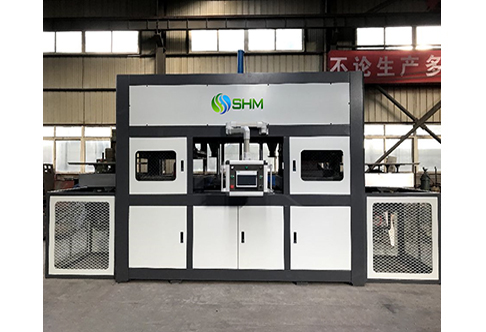

Machine Main Features

1. High precision,high stability;

2. Forming and hot-pressing two-in-one design;

3. Two hot pressing platen with one forming platen design, improve efficiency;

4. Off-line auto trimming, more stable;

5. Position, pressure and temperature can be adjusted accurately.

How to Choose A Tableware pulp molding machine?

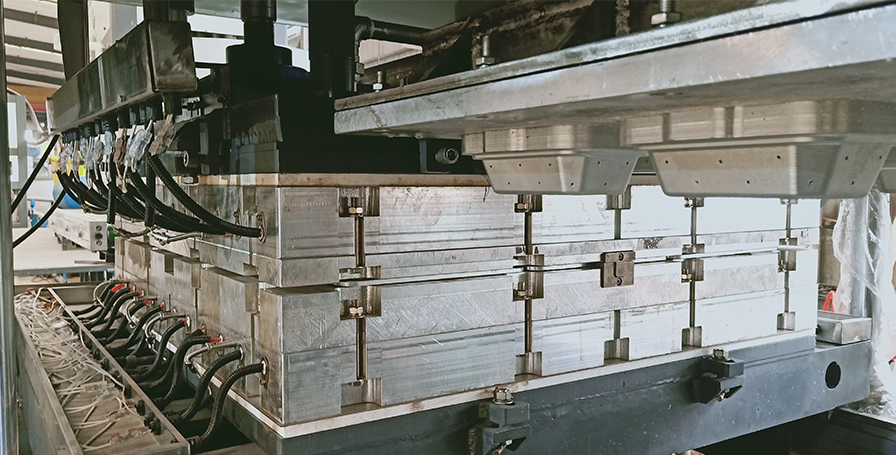

ZMC 1150 mold platen size: 1150*1150mm

ZMC 900 mold platen size: 920*920mm

Mold raw material: Aluminum.

Cast aluminum are highly recommended for both forming and transfer mould. Compared with other material, cast aluminum mould character:

1. with higher corrosion resistance, proper strength, hardness and heat endurance

2. have better durability;

3. featured with better machine, which will shorten tooling cycle;

4. widely used in molded pulp industry;

5. surface is polished and proceed machining with CNC’s ensure precision.

- Stability of Control System

- Stability of Control System

All systems involved in the paper pulp production process are closely linked with each other. The systems work automatically as per the operational settings. Therefore, a steady and durable control system is needed to make sure that each process is performed accurately and simultaneously.

- Qualification Rate

Qualification rates directly reflect the productivity of the machine and also the working state of the molding machine. To manufacture efficient and up to the mark products, the mold should be clean, perfect in size and shape, and should be robust and sturdy. So you can get good quality degradable molded paper tableware.

- Safety, Maintainability & Operability

Safety is an essential thing in the molding process. There are special training given to the workers working on the molding machines. Paper molding machines need to be cleaned on a regular basis to maintain their operational efficiency.

Get Best Molded Pulp Machine Price

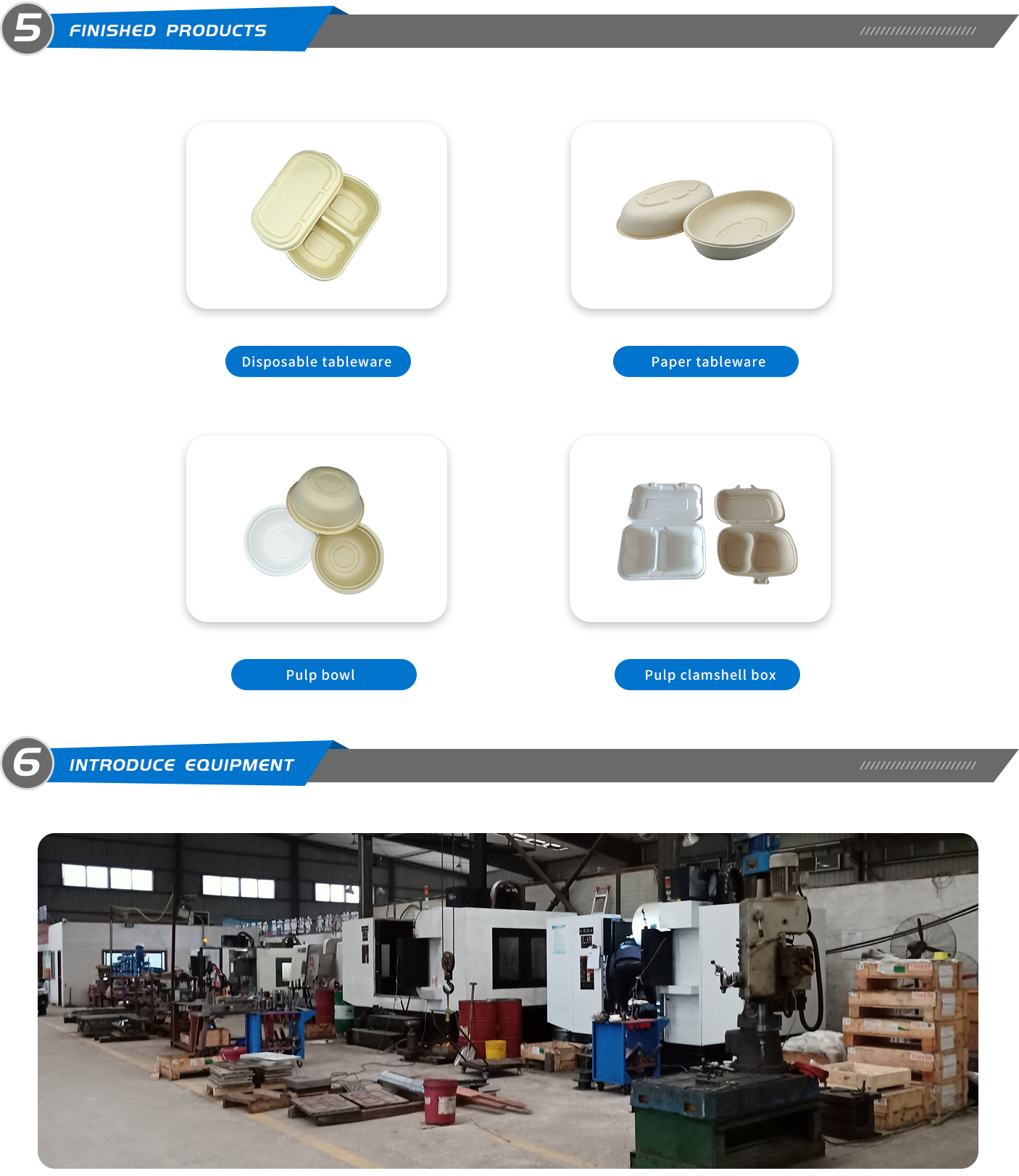

Molded pulp machine is used to produce disposable pulp molded dinnerware. The production line uses pulp from sugarcane, bamboo, wood, reeds, straw and other pulp boards as raw materials, machine could make all kinds of eco-friendly disposable bamboo paper pulp plate food container bowl.

Looking for a biodegradable disposable bagasse pulp moulding machine for disposable plates lunch box, SHM offer prototype tooling in our work shop. With our sample machine we can produce in-house samples for product trials. This will ensure the product your customer needs is what they get

Molded pulp raw material

Molded pulp raw material: natural fiber pulp including alternative non-wood pulps such as sugarcane/bagasse/straw/bamboo pulp board.

Why choose SHM?

SH Machinery has engaged in pulping molding filed since 1986.

Advantages includes:

Advantages includes:

1. 30 years technology accumulation for EU,USA PRODUCT manufacturers

2. Approvals from Top 10 USA packaging company

3. CE and ISO9001 certificate

4. OEM and ODM both accepted.

5. Own designing team for new products development

6. Quick delivery time for decent orders

7. 24 hours online sales/after sales services

SERVICE

1. Engineering research and technical consultation;

2. Manufacture;

3. Project Schedule;

4. Preparation of documents and drawings;

5. Training of maintenance and operation personnel;

6. Guide Assembly line installation;

7. Electrical and mechanical design;

8. System integration;

9. System test and handover;

10. One year of after-sales support;

11. Spare parts are included;

12. Installation within the scope of supply;

13 Operation support for the buyer’s factory;

14. System test after equipment delivery;

15. Documentation of assemble line.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED