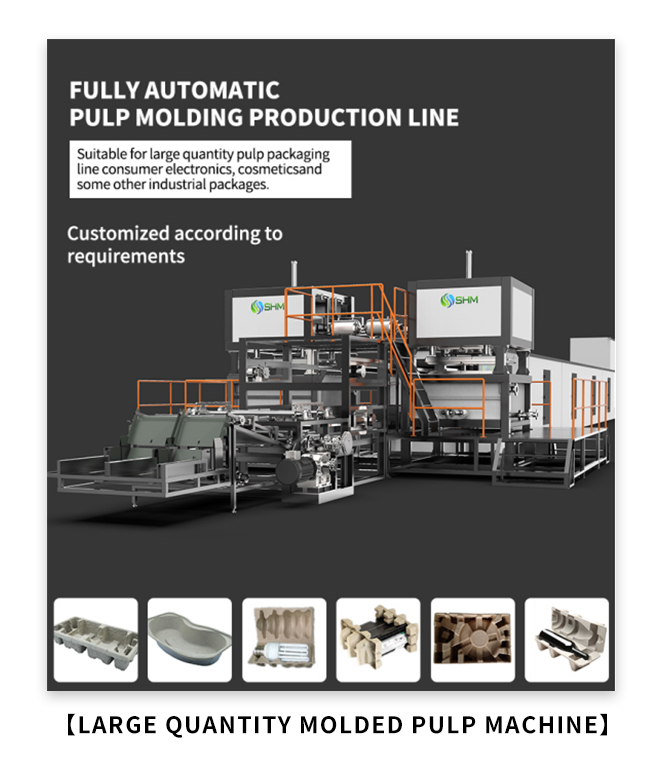

SHM: Your Trusted Source for Innovative Pulp Molding Solutions

The SHM paper cup making machine integrates pulp molding technology, pulp molding equipment with a metal drying line for efficient and sustainable production. This fiber molded system excels in crafting paper cups through a seamless process—from pulp preparation to forming and final drying. At the same time, we can also use the wet pulp molding method to provide paper cup lid making machine and paper cup making machine.

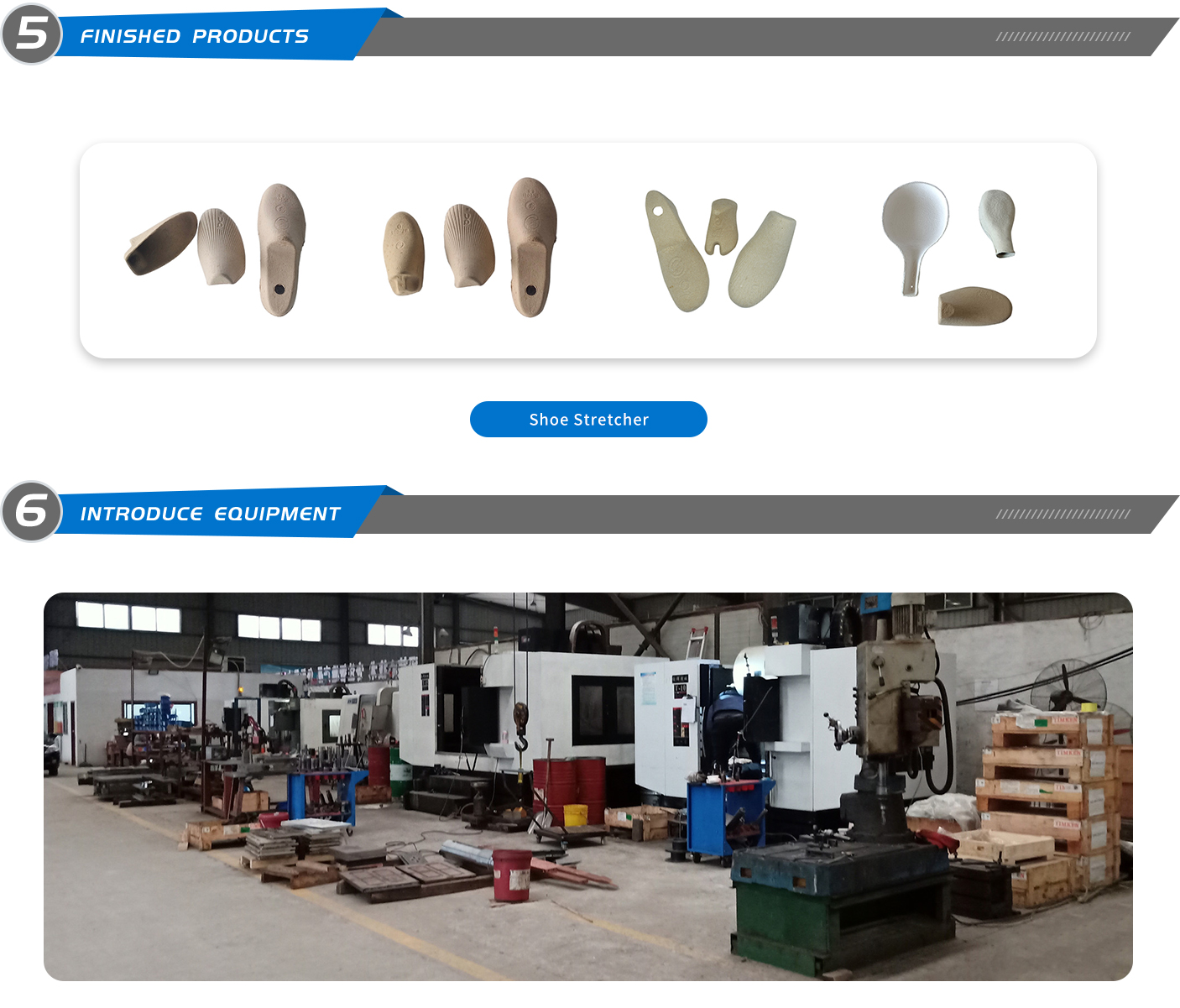

-All processed parts have a processing accuracy of level 8 or above and have undergone heat treatment processes

-The processing accuracy of the transmission structure is C5 level

-All bearings Japan NSK

-Main electrical components Siemens

-Burner Italian Riello

-Drying line insulation layer 120kg/m3

-Variable frequency circulation fan

-The main engine is powered by a hydraulic mechanism

-Equipped with fault overload protection device to prevent chain overload and breakage, resulting in maintenance difficulties and greater equipment damage.

-Adjustable speed control system to help adjust the production speed.

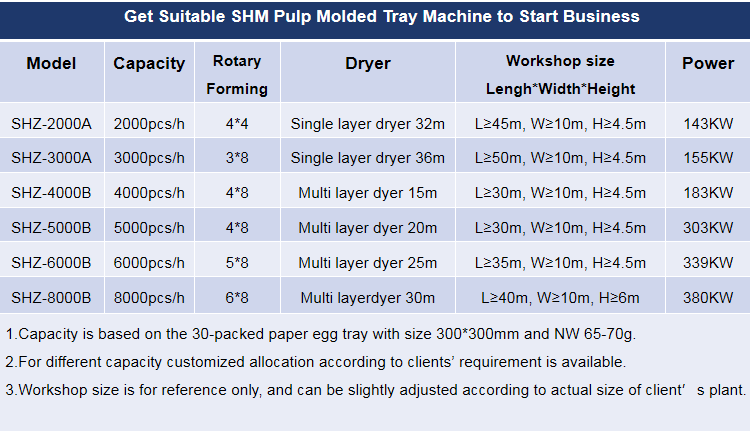

Get a complete solution for your paper paper tray production line from SHM now, we will reply you in 24 hours.

Who are we?

We are based in Hunan, China, start from 2007, SHM is a global supplier of high-quality molded fiber packaging tray production lines, we provide sustainable and innovative solutions for the food service and packaging market.

In 1986, the founder of the company Mr Chao started his work at pulp molding industry, under his leadership, the first domestic pulp molding rotary drum egg tray production line was designed. and holds a number of pulp molding patents.

In 2007, SHM was established.

In 2014, SHM participated in the formulation of industry standards for pulp molding in China.

2. How can we guarantee quality?

Automatic pulp molding equipment factory direct,we attach great importance to quality;

Approvals from Top 5 USA packaging companies;

Owns CE and ISO9001 certificates;

Owns 40+patents.

High-tech enterprise for 13+ years

Alibaba member for 15+years

3.What kind of pulp molded machine can you buy from us?

Pulp molding tableware machine;

Pulp molding machine for industrial package trays;

Egg trays and boxes making machine;

All in one small pulp molding machine for laboratory or sampling;

Nursery Tray Making Machine;

Fruit Tray Making Machine;

Coffee Cup Tray Machine.

SERVICE

1. Engineering research and technical consultation;

2. Manufacture;

3. Project Schedule;

4. Preparation of documents and drawings;

5. Training of maintenance and operation personnel;

6. Guide Assembly line installation;

7. Electrical and mechanical design;

8. System integration;

9. System test and handover;

10. One year of after-sales support;

11. Spare parts are included;

12. Installation within the scope of supply;

13 Operation support for the buyer’s factory;

14. System test after equipment delivery;

15. Documentation of assemble line.

RELATED

RELATED