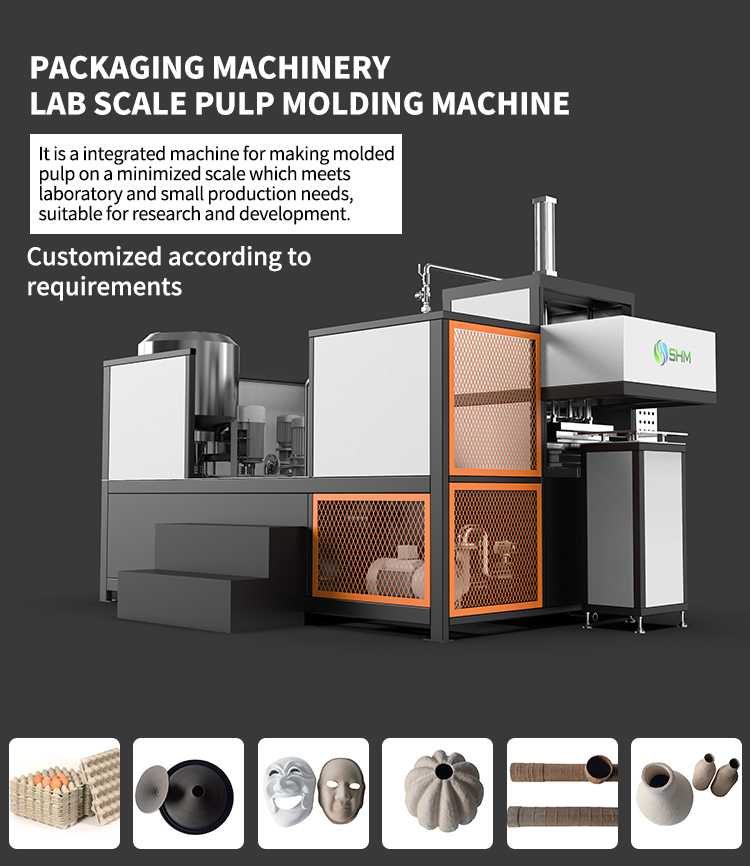

SHM Small Paper Packaging Molding Machine, a versatile solution for small-scale, eco-friendly packaging production. This pulp molding machine is designed with simplicity and efficiency in mind, providing an integrated forming process, minimal infrastructure requirements, and ease of control for cost-effective operation. It can be used to shape multiple different types of pulp forms. egg cartons, nursery containers, pint and food containers and clam shells, etc.

Single Metal Drying Line:

The paper pulp forming machine features a single metal drying line for efficient drying of molded paper packaging. This design ensures simplicity, streamlining the production process.

Integrated Forming Machine:

Enjoy the convenience of an integrated forming machine that combines the pulp molding process seamlessly. This integration optimizes space and operational efficiency.

No Infrastructure Required:

Designed for flexibility, this machine requires minimal infrastructure, making it ideal for small-scale operations. No extensive setup is needed, allowing for quick deployment and production initiation.

Compact Size:

The small footprint of this molded pulp machine makes it suitable for limited spaces. Whether in a small workshop or home-based setting, it maximizes usability without compromising on functionality.

Easy Control Interface:

Benefit from an intuitive control interface that simplifies operation. The user-friendly controls make it easy to manage the entire molding process, even for those new to the technology.

Robust Stainless Steel Construction:

Built to withstand the rigors of production, the machine boasts a robust stainless steel construction. This ensures durability, resistance to corrosion, and longevity in operation.

Built-in Air Compressor and Reservoir:

The inclusion of a built-in air compressor and reservoir enhances operational efficiency. This integrated system provides the necessary pressure for molding without the need for external components.

Cost-Effective Production:

Offering a cost-effective solution for small-scale packaging production, this machine allows businesses to enter the market with minimal investment while contributing to sustainable practices.

Reach out to SHM to inquire about the Small Paper Packaging Molding Machine. Discuss your requirements and receive guidance on the most suitable model for your needs.

Once ordered, the machine will be delivered with clear setup instructions. The minimal setup requirements ensure a quick and hassle-free installation process.

Transform your small-scale operation into a hub of eco-friendly packaging innovation with the SHM Small Paper Packaging Molding Machine. Start your journey towards sustainable and cost-effective production today.

1.Who are we?

We are based in Hunan, China, start from 2007, SHM is a global supplier of high-quality molded fiber packaging tray production lines, we provide sustainable and innovative solutions for the food service and packaging market.

In 1986, the founder of the company Mr Chao started his work at pulp molding industry, under his leadership, the first domestic pulp molding rotary drum egg tray production line was designed. and holds a number of pulp molding patents.

In 2007, SHM was established.

In 2014, SHM participated in the formulation of industry standards for pulp molding in China.

2. How can we guarantee quality?

Automatic pulp molding equipment factory direct,we attach great importance to quality;

Approvals from Top 5 USA packaging companies;

Owns CE and ISO9001 certificates;

Owns 40+patents for pulp molding machines.

High-tech enterprise for 13+ years

Alibaba member for 15+years

3. What kind of pulp molded machine can you buy from us?

Pulp molding tableware machine;

Bagasse pulp molding machine for industrial package trays;

Egg trays and boxes making machine;

All in one small pulp molding machine for laboratory or sampling;

Nursery Tray Making Machine;

Fruit Tray Making Machine;

Coffee Cup Tray Machine.

4.Do you have the lay out of the pulp molding production line ?

A: Yes, we usually provide the layout drawing of the production line after the customer confirms the purchase intention or signs the contract.

5.How do you ship the goods and how long does it take to arrive?

A: Usually goods shipped by sea, arrive time up to the order and destination port .

6.How to proceed an order for pulp molded tray machine?

A: Firstly, let us know your requirements or application.

Secondly, we quote according to your requirements or our suggestions.

Thirdly, sign the contract and you pay the deposit

Fourthly, we arrange the production ...pay the balance, goods packaging and delivery.

SERVICE

1. Engineering research and technical consultation;

2. Manufacture;

3. Project Schedule;

4. Preparation of documents and drawings;

5. Training of maintenance and operation personnel;

6. Guide Assembly line installation;

7. Electrical and mechanical design;

8. System integration;

9. System test and handover;

10. One year of after-sales support;

11. Spare parts are included;

12. Installation within the scope of supply;

13 Operation support for the buyer’s factory;

14. System test after equipment delivery;

15. Documentation of assemble line.