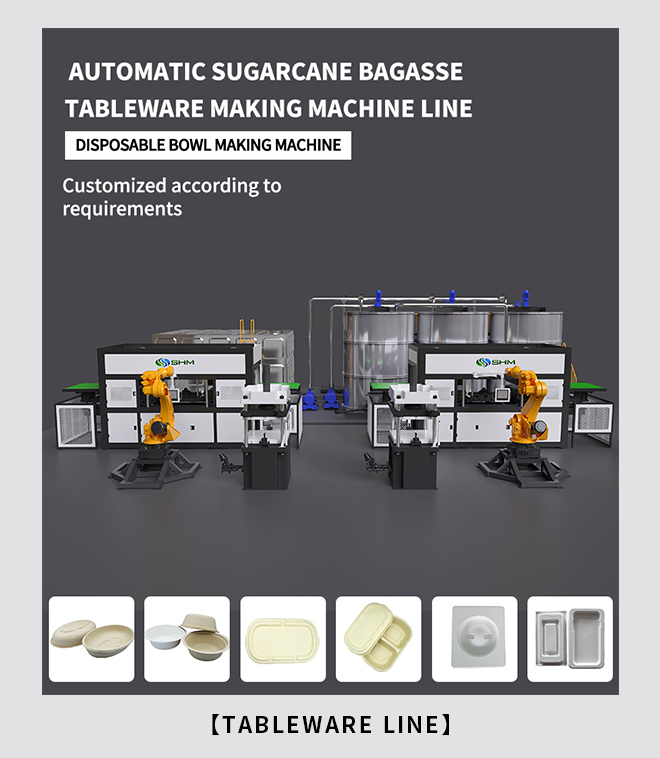

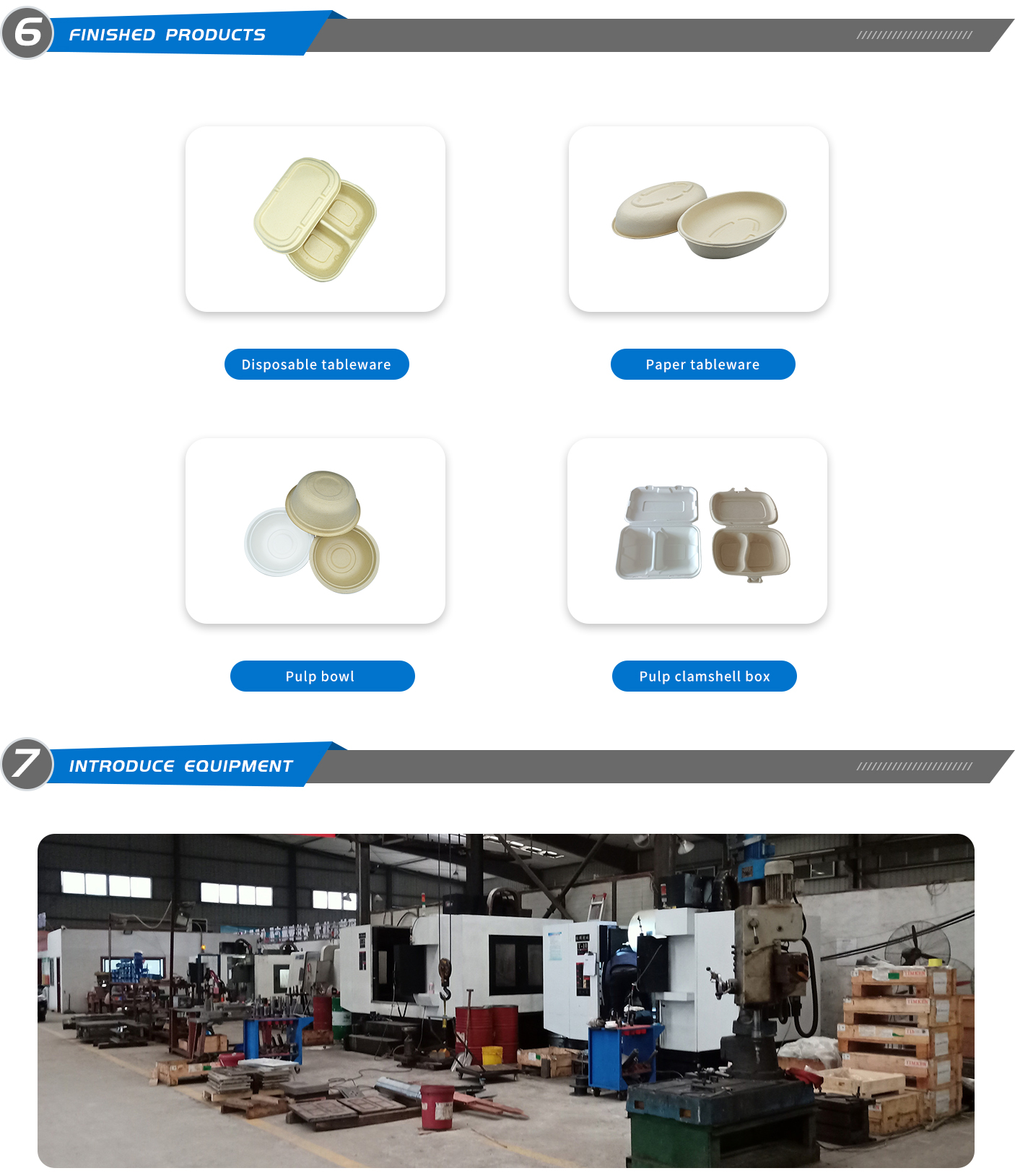

SHM Biodegradable Tableware Production Line also called biodegradable bagasse plate making machine, it is an advanced and eco-friendly solution for the efficient manufacturing of biodegradable tableware, with a focus on producing biodegradable bagasse plates/bowls and clamshell boxes . This fiber molded production line integrates key components to ensure a seamless and sustainable process. Tableware making machine biodegradable include the pulping system, pulp thermoforming machine (for forming and hot pressing), and edge trimming.

Customization options for sugarcane pulp plate making machines can vary depending on customization options:

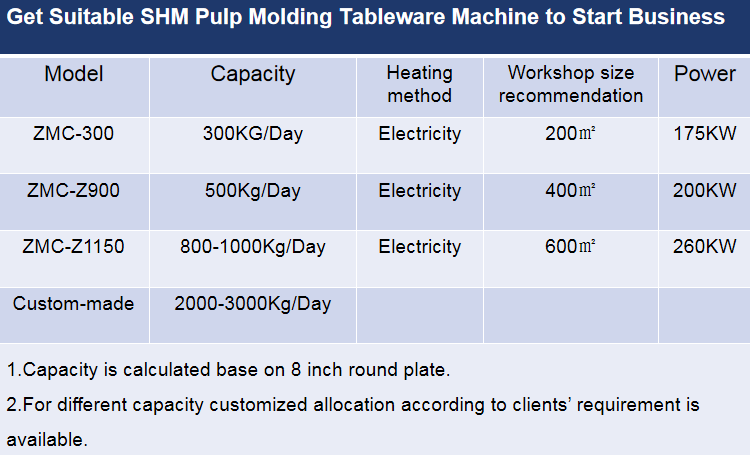

Production Capacity

Plate Size and Shape

Automation Level

Energy Efficiency

Mold Options

Brand and Logo Imprinting: Some machines can be customized to imprint your brand name or logo on the plates for branding purposes.

Pulping System:

Incorporates a robust pulping system capable of processing a variety of raw materials.

Handles sugarcane bagasse pulp, wood pulp, straw pulp, bamboo pulp, and other types obtained after paper processing.

Customer can choose the raw material according to their product requirement.

Pulp Thermoforming Machine (Forming and Hot Pressing):

Advanced pulp thermoforming machine that combines forming and hot pressing stages in a single unit.

Enables precise shaping of biodegradable plates with consistent quality and efficiency.

Edge Trimming:

The tableware pulp molding production line includes a dedicated edge trimming process for refined and uniform edges on the biodegradable plates.

Enhances the overall appearance and quality of the final products.

But sometimes this progress is optional at different requirement.

SHM is a global supplier of high-quality molded fiber packaging production lines, we provide sustainable and innovative solutions for the food service and packaging market.

In 1986, the founder of the company Mr Chao started his work at pulp molding industry, and holds a number of pulp molding patents.

In 2007, SHM was established;

In 2014, SHM participated in the formulation of industry standards for pulp molding in China;

SHM team pay great importance to quality, automatic pulp molding equipment factory direct;

Owns CE and ISO9001 certificates;

13+ years high-tech enterprises in China;

15+ years Alibaba member;

SHM owns 40+patents for fiber molded machines;

Approvals from Top 5 USA packaging companies.

What is the difference between bagasse and pulp?

Bagasse and pulp are related terms, but they refer to different stages and forms of processed plant fibers. Here's a brief explanation of the difference between bagasse and pulp:

1.Bagasse:

Definition: Bagasse is the fibrous byproduct that remains after extracting juice from sugarcane or other plants.

Source: It is primarily sourced from sugarcane, but it can also come from other plants like bamboo, wheat, or rice.

Composition: Bagasse is rich in cellulose fibers and may contain some residual sugars.

Characteristics: It is coarse, fibrous, and typically has a moisture content.

Common Use: Bagasse is often used as a raw material in various industries, especially for the production of paper and biodegradable products.

2.Pulp:

Definition: Pulp is a processed form of plant fibers obtained through a mechanical or chemical process to break down the raw material into a fibrous mass.

Source: Pulp can be made from various plant sources, including wood, recycled paper, and agricultural residues like bagasse.

Composition: Pulp consists of individual fibers that have been separated from the raw material and can be refined further for different applications.

Characteristics: Pulp can be classified into different types, such as mechanical pulp and chemical pulp, based on the processing method.

Common Use: Pulp is a key ingredient in the production of paper, cardboard, and various other products. It is also used in the manufacturing of biodegradable materials, such as molded pulp products.

In summary:

Bagasse is the raw, fibrous byproduct derived from sugarcane or other plant processing.

Pulp is the processed form of plant fibers obtained through mechanical or chemical processes and can be made from various sources, including bagasse.

In the context of the production of biodegradable tableware, bagasse is often used as a raw material that undergoes a pulping process to create a pulp slurry, which is then molded and formed into the final products.

SERVICE

1. Engineering research and technical consultation;

2. Manufacture;

3. Project Schedule;

4. Preparation of documents and drawings;

5. Training of maintenance and operation personnel;

6. Guide Assembly line installation;

7. Electrical and mechanical design;

8. System integration;

9. System test and handover;

10. One year of after-sales support;

11. Spare parts are included;

12. Installation within the scope of supply;

13 Operation support for the buyer’s factory;

14. System test after equipment delivery;

15. Documentation of assemble line.

RELATED

RELATED