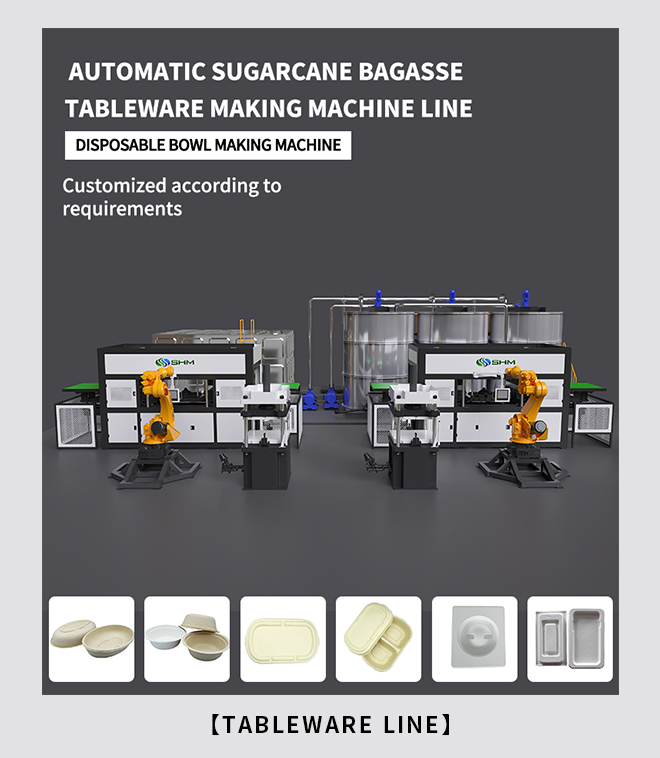

SHM is one of the leading tableware pulp molding machine supplier in China ,it has devoted to the design and manufacture of pulp moulding production line, pulp moulding machines, hot pressing equipment and hot press molds . We accept customized pulp molding shape and molded pulp tray, such as paper cup cover making machine, disposable dinnerware pulp molding machine,pulp molding machine production line etc.

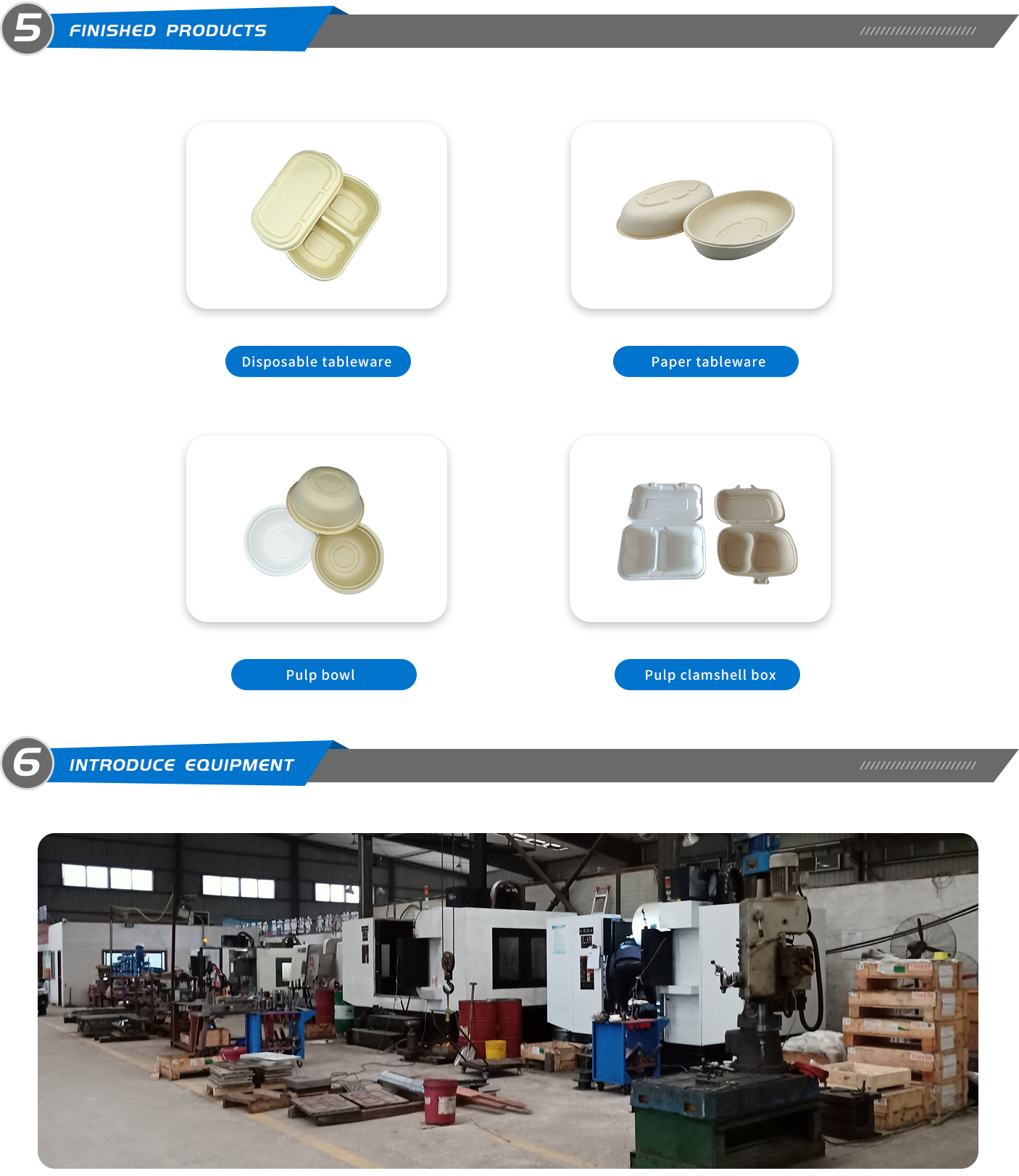

The pulp molded tableware production line is composed of a pulping system, forming equipment, vacuum system, high pressure water system and an air compressor system, and is used to produce disposable pulp molded dinnerware. The production line uses pulp from sugarcane, bamboo, wood, reeds, straw and other pulp boards as raw materials. The materials are prepared into a pulp with a certain concentration through the processes of hydra pulping, refining, adding chemical additives, etc. They are evenly attached to a special metal mold to form a wet blank product. A disposable pulp molded tableware product is produced through the processes of drying, hot pressing, trimming, and stacking. The average unit capacity of the forming system is 1Ton / day. And It can be customized per the actual order from the customer.

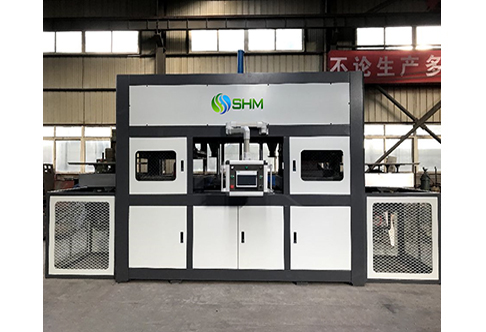

Machine Main Features

1. High precision,high stability;

2. Forming and hot-pressing two-in-one design;

3. Two hot pressing platen with one forming platen design, improve efficiency;

4. Off-line auto trimming, more stable;

5. Position, pressure and temperature can be adjusted accurately.

How to Choose A Tableware pulp molding machine?

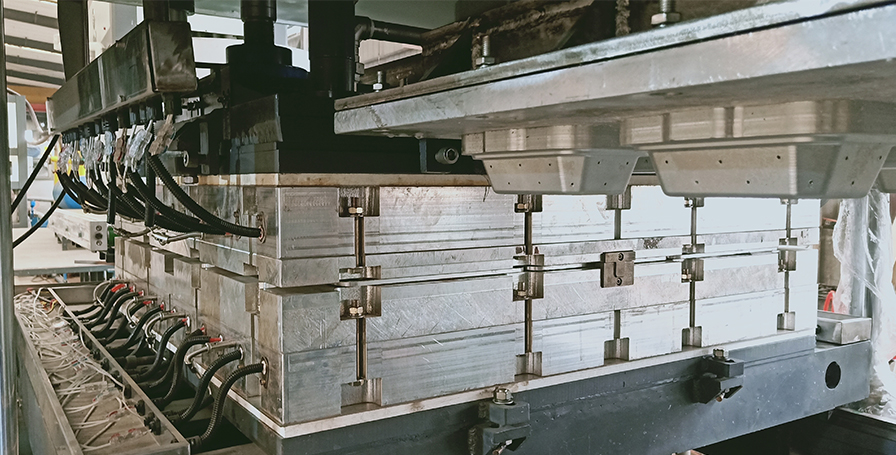

ZMC 1150 mold platen size: 1150*1150mm

ZMC 900 mold platen size: 920*920mm

Mold raw material: Aluminum.

Cast aluminum are highly recommended for both forming and transfer mould. Compared with other material, cast aluminum mould character:

1. with higher corrosion resistance, proper strength, hardness and heat endurance

2. have better durability;

3. featured with better machine, which will shorten tooling cycle;

4. widely used in molded pulp industry;

5. surface is polished and proceed machining with CNC’s ensure precision.

- Stability of Control System

- Stability of Control System

All systems involved in the paper pulp production process are closely linked with each other. The systems work automatically as per the operational settings. Therefore, a steady and durable control system is needed to make sure that each process is performed accurately and simultaneously.

- Qualification Rate

Qualification rates directly reflect the productivity of the machine and also the working state of the molding machine. To manufacture efficient and up to the mark products, the mold should be clean, perfect in size and shape, and should be robust and sturdy. So you can get good quality degradable molded paper tableware.

- Safety, Maintainability & Operability

Safety is an essential thing in the molding process. There are special training given to the workers working on the molding machines. Paper molding machines need to be cleaned on a regular basis to maintain their operational efficiency.

Find a Qualified Paper Pulp Molding Machines Manufacturer

Fibre molding is a great environmentally friendly technology that delivers compostable food packaging containers. All pulp tableware production line and pulp molds could be customized.

About SHM fully automatic sugarcane bagasse pulp molding machine, pulp molding is the process of shaping liquid pulp material by using a rigid structure generally known as paper pulp molding machine. Pulp board can be transferred into any desired shape using a mold of that shape. The molding process is applied when a certain shape of the object is to be produced in large quantities.

Looking for a custom product, we offer prototype tooling in our work shop. With our sample machine we can produce in-house samples for product trials. This will ensure the product your customer needs is what they get.

Molded pulp raw material

Molded pulp raw material: natural fiber pulp including alternative non-wood pulps such as sugarcane/bagasse/straw/bamboo pulp board.

Why choose SHM?

SHM is a global supplier of high-quality molded fiber packaging production lines, we provide sustainable and innovative solutions for the food service and packaging market.

In 1989, the founder of the company Mr Chao started his work at pulp molding industry, and holds a number of pulp molding patents.

In 2007, SHM was established.

In 2014, SHM participated in the formulation of industry standards for pulp molding in China.

Automatic pulp molding equipment factory direct, SHM team pay great importance to quality;

Approvals from Top 5 USA packaging companies;

Have CE and ISO9001 certificates;

SHM owns 40+patents for fiber molded machines.

SERVICE

1. Engineering research and technical consultation;

2. Manufacture;

3. Project Schedule;

4. Preparation of documents and drawings;

5. Training of maintenance and operation personnel;

6. Guide Assembly line installation;

7. Electrical and mechanical design;

8. System integration;

9. System test and handover;

10. One year of after-sales support;

11. Spare parts are included;

12. Installation within the scope of supply;

13 Operation support for the buyer’s factory;

14. System test after equipment delivery;

15. Documentation of assemble line.

RELATED

RELATED