SHM is devoted to the design and manufacture of pulp moulding machines, pulp moulding dies, hot pressing equipment and hot press dies.

Specialize in highly-challenging mold design, pulp mould maker, development with 30+ year experience.

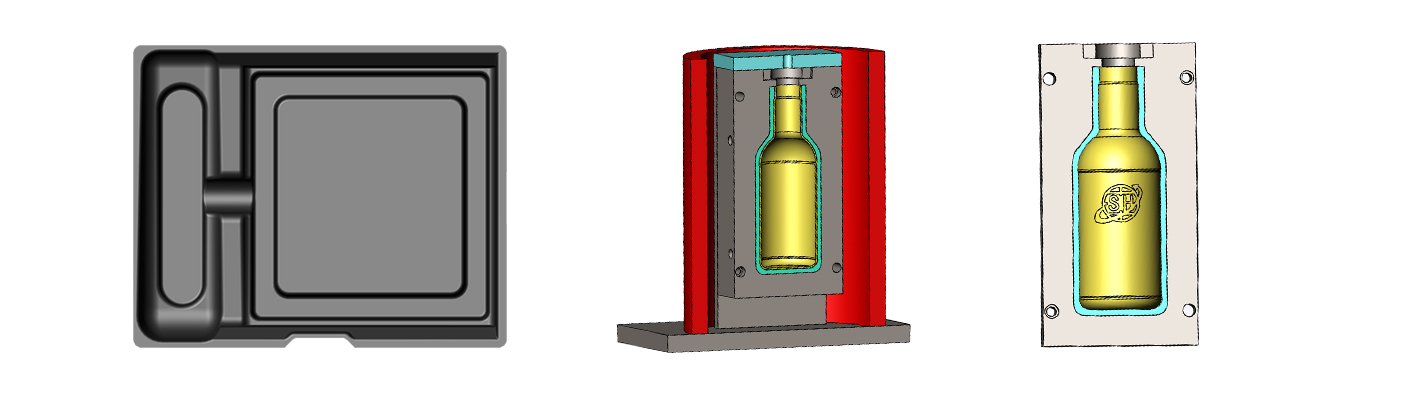

SHM has different customized tray molds to choose from, including electronics packaging tray, bottle wine tray, cosmetic packaging tray e. Also, we have a professional design team and engineers to customize the molds according to your needs, for example,take out trays,apple tray mold, shoe support tray, seedling trays, coffee trays, etc, you can get all kinds of customized pulp molds from us.

Pulp Molding Dies

Designing the 1st screen stage is an art form. From years of building pulp moulding tooling, we can predict how the pulp will collect on the screen in any given shape, slope, groove, pocket and how to accommodate proper vacuum holes and channels under the screen so that the finished product will have uniform thickness and density on all sides and faces.

No hand drilling

Our pulp molding dies are machined and drilled on 5 axis CNC mill to exact specification, instead of being drilled by hand and channels ground with a hand grinder. Our tools are built in modular fashion with bolted inserts so that you can change just the damaged cavity and continue running production instead of pulling the entire mold out and waiting for repairs/replacements.

Why choose SHM?

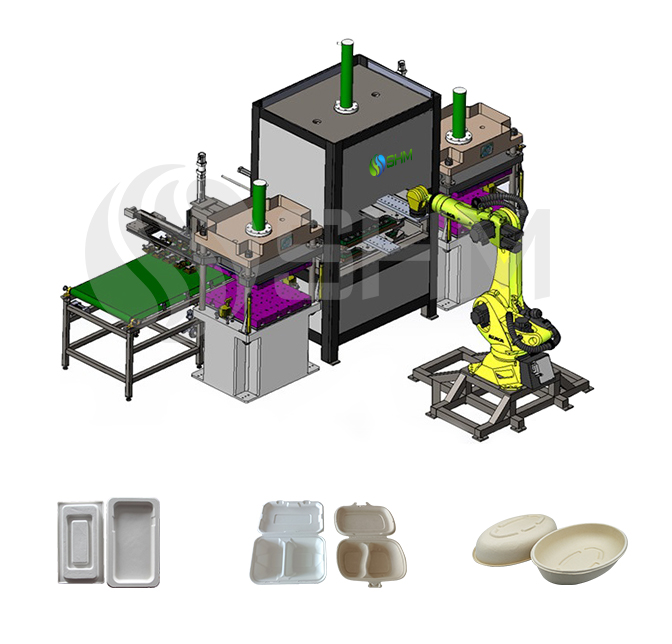

SHM is a global supplier of high-quality molded fiber packaging production lines, we provide sustainable and innovative solutions for the food service and packaging market.

In 1989, the founder of the company Mr Chao started his work at pulp molding industry, and holds a number of pulp molding patents.

In 2007, SHM was established.

In 2014, SHM participated in the formulation of industry standards for pulp molding in China.

Automatic pulp molding equipment factory direct, SHM team pay great importance to quality;

Approvals from Top 5 USA packaging companies;

Have CE and ISO9001 certificates;

SHM owns 40+patents for fiber molded machines.

Service Ability

1. Engineering research and technical consultation;

2. Manufacture;

3. Project Schedule;

4. Preparation of documents and drawings;

5. Training of maintenance and operation personnel;

6. Guide Assembly line installation;

7. Electrical and mechanical design;

8. System integration;

9. System test and handover;

10. One year of after-sales support;

11. Spare parts are included;

12. Installation within the scope of supply;

13 Operation support for the buyer’s factory;

14. System test after equipment delivery;

15. Documentation of assemble line.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED