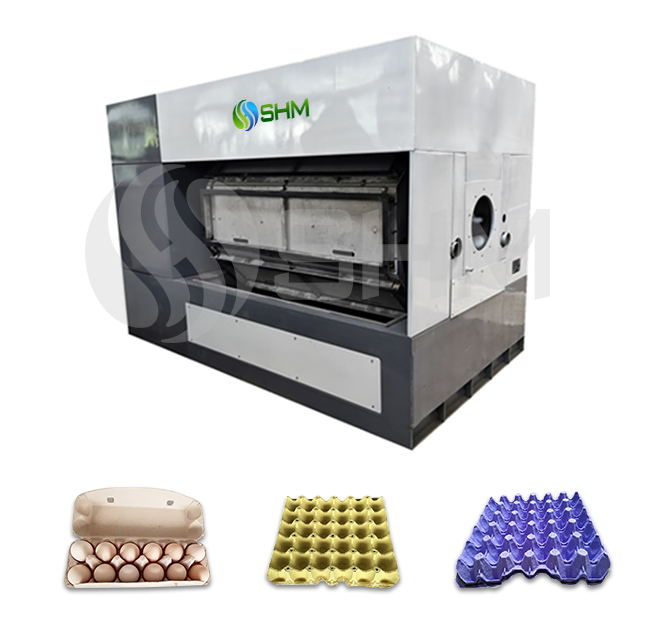

SHM Egg Tray Making Machine is used to make paper egg trays with the waste paper. Small business waste paper recycling egg tray egg carton box making machine, also could be manual egg tray machine or semi-automatic paper egg tray machine, it is used to make recycle paper into various paper trays, such as egg trays egg box, fruit packaging tray, wine bottle tray etc.

Pulp egg tray machine assembly instructions:

Following eggs tray carton making machine is for 2000pcs/hour, get automatic egg tray machine price, just send us an inquiry on the page to get more information.

Egg Trays Pulping System

Making pulp is the first step to make paper pulp egg cartons egg trays, which is applicable to turning recycle paper into pulp. As we know, the smoother the paper pulp is, the better the molded products are. The pulping system turns raw materials into pulp of certain consistency through pulping, screening, and chemical additives adding. This is the first step for the whole line.

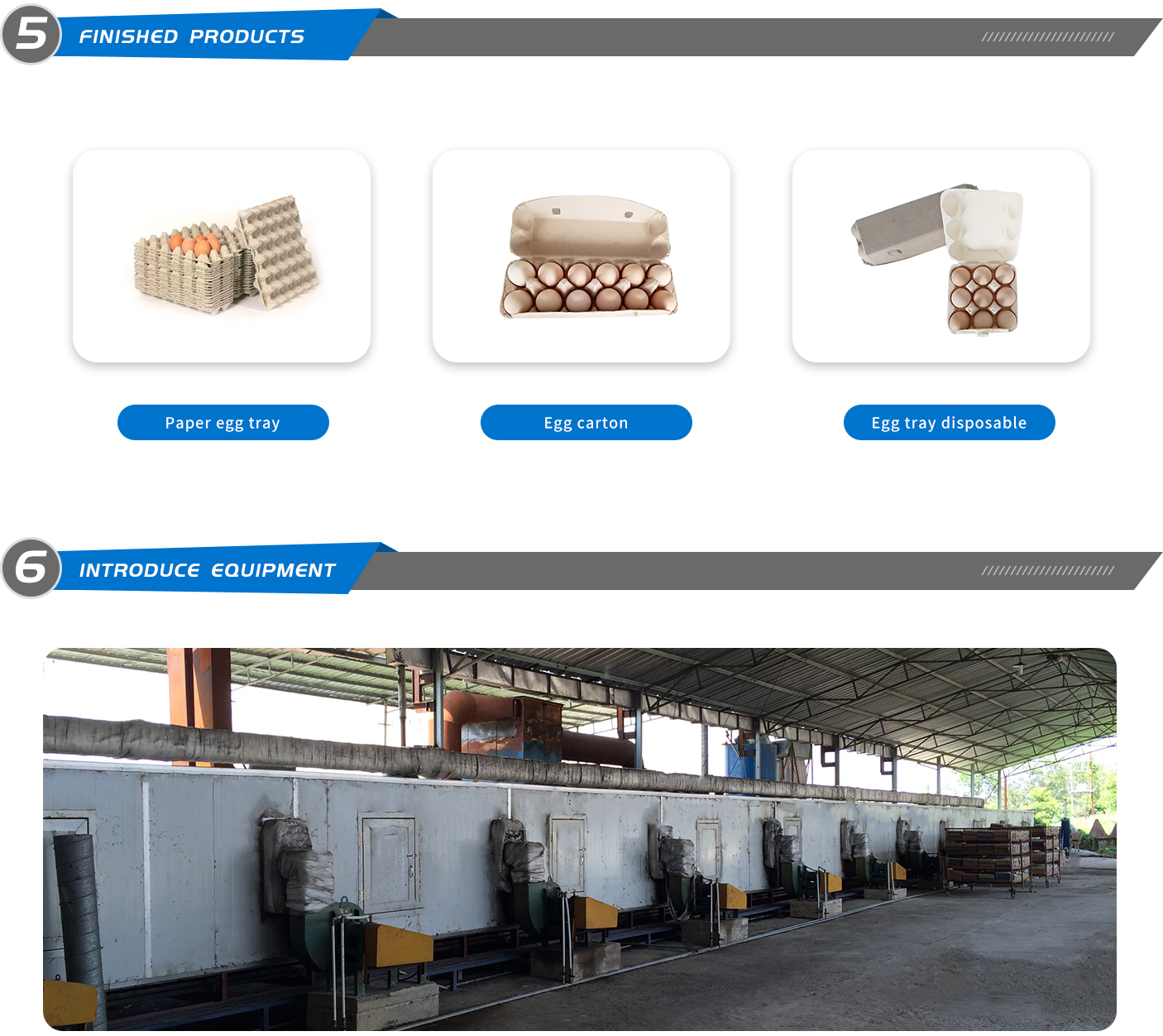

SHM offers a complete and fully automatic machinery set-up from raw materials processing to after treatment and product packaging, as well as comprehensive service and a technology support concept that helps you optimize your molded fibre packaging production.

The pulp preparation system can be customized according to local requirements and raw material specifications.

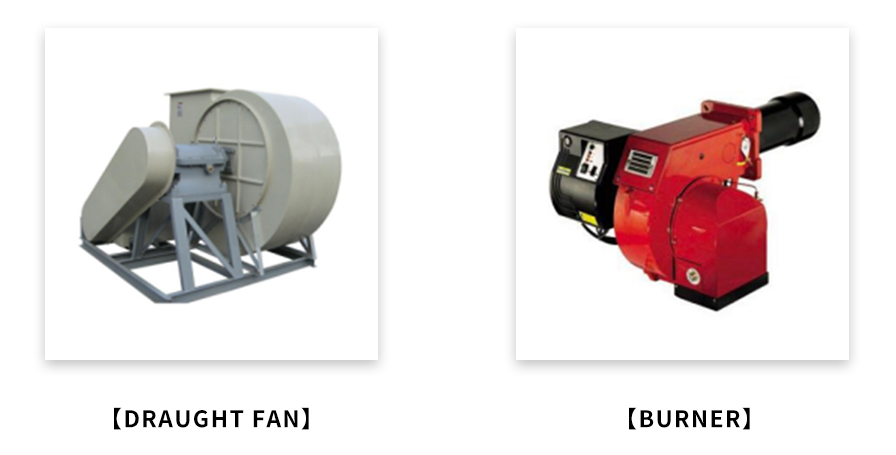

Egg tray drying machine

After forming, the egg tray will enter the drying system automatically; This is a multi- drying system. It can save energy and factory area ; The temperature of each section can be adjusted independently; burners with international famous brand.The energy of option: LPG,nature gas, diesel oil. Equipped with auto control cabinet.

- Consist of 8pcs of forming platens and 1 pc of transfer platen;

- Platen size: 1450 x 450mm. 4pcs of 30-cell egg tray molds can be mounted on each forming platen(4pcs/cycle).There are 16pcs of forming molds and 4pcs of transfer molds in total;

- Forming efficiency:10cycles/min;

- Equip with vacuum auto drain system, preheating system, auto cleaning system for the forming mold and auto control cabinet.

The main shaft is made of 40Cr material, the main shaft diameter is 120mm, the drum fixing plate and the mold template are processed by 10mm 304 stainless steel plate, the slurry pool is 3mm 304 stainless steel; the vacuum tube is 304 stainless steel, steel thickness of main body:8mm, and the connection mode is detachable hard connection, which can enhance the rotating drum stability;

The bearings all use the Japanese NSK brand;

Abandon the traditional PVC intake pipe, changed to stainless steel intake structure.

How Does A Rotary Egg Tray Machine Work?

In general, an egg tray production line converts waste paper, from cardboard to newspaper, into various paper trays. A complete production line starts with a pulp making machine, throughout a pulp moulding machine, to a drying and packing system. While the rotary molding machine is the most important equipment. It looks like a large drum so that someone also calls it as drum-type egg tray machine. Taking 8-sided egg tray making machine as an example, there are 8 sides of forming molds, which keep spinning and being filled with the prepared pulp. When the forming molds move to the transfer mold, the wet paper trays will be demolded. Meanwhile, the cleaning system will flush the residuals on the forming molds quickly. As we can see, this entire process is of high continuity. That’s why the operating speed is much higher.

Please feel free to send us an inquiry if you want to consult this kind of egg tray making machine automatic. We will make suggestions according to your requirement.

The waste paper can be old newspapers,100% carton, old books, old hard paper case, waste paper cup and so on. You can produce all colors of egg tray box, such as blue, pink, white, green, yellow and son on. It is a very interesting thing. SHW has egg carton tray machine for sale.

Why choose SHM?

SHM is a global supplier of high-quality molded fiber packaging production lines, we provide sustainable and innovative solutions for the food service and packaging market.

In 1989, the founder of the company Mr Chao started his work at pulp molding industry, and holds a number of pulp molding patents.

In 2007, SHM was established.

In 2014, SHM participated in the formulation of industry standards for pulp molding in China.

Automatic pulp molding equipment factory direct, SHM team pay great importance to quality;

Approvals from Top 5 USA packaging companies;

Have CE and ISO9001 certificates;

SHM owns 40+patents for fiber molded machines.

SERVICE

1. Engineering research and technical consultation;

2. Manufacture;

3. Project Schedule;

4. Preparation of documents and drawings;

5. Training of maintenance and operation personnel;

6. Guide Assembly line installation;

7. Electrical and mechanical design;

8. System integration;

9. System test and handover;

10. One year of after-sales support;

11. Spare parts are included;

12. Installation within the scope of supply;

13 Operation support for the buyer’s factory;

14. System test after equipment delivery;

15. Documentation of assemble line.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED