Are you seeking an all-in-one solution for large-scale egg carton production that encompasses the entire process from raw materials to final packaging? Look no further. The SHM Big Quantity Waste Paper Egg Carton Maker Production Line is a comprehensive and efficient solution that integrates pulping, forming, drying, and packing systems into one seamless production line.

Scope of supply:

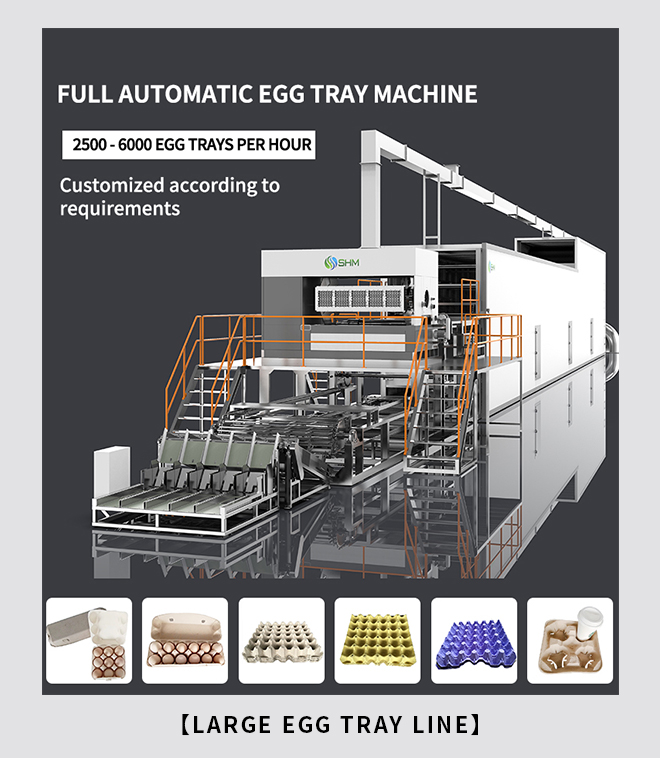

1.High Production Capacity: SHM Egg Carton Maker Production Line is designed to meet the demands of high-volume paper egg carton production. With an impressive production capacity, it can generate a significant quantity of egg cartons per hour, making it the perfect choice for commercial egg farms and packaging facilities.

2.Fully Automated Operation: This production line is fully automated, eliminating the need for extensive manual labor. It streamlines the entire waste paper egg carton production process, starting with pulping and ending with final carton packing.

3.Pulping System: The pulping system efficiently transforms recycled waste paper materials into high-quality pulp. It is versatile and can handle a wide range of paper waste, contributing to sustainability efforts and reducing the environmental footprint.

4.Forming System: The forming system expertly molds the pulp into precise and uniform egg carton shapes. It can be customized to produce various egg carton styles, accommodating different egg sizes and packaging requirements.

5.Drying System: The integrated drying system, complete with metal drying components, ensures rapid and efficient drying of the formed egg cartons. It offers temperature and timing controls to optimize the drying process, resulting in top-notch product quality.

6.Packing System: This production line doesn't stop at forming and drying; it includes a packing system that simplifies the packaging process. It's designed to efficiently prepare egg cartons for distribution or sale.

Related Parameters:

1.Reduces labor costs through full automation.

2.Enhances product quality, consistency, and packaging efficiency.

3.Promotes eco-friendly practices by using recycled paper materials.

4.Maximizes production efficiency and minimizes processing time.

5.Offers a reliable, long-lasting solution for your large-scale egg carton production needs.

- Power: 11KW;

- Power: 11KW;

- Consist of 8pcs of forming platens and 1 piece of transfer platen;

- Platen size: 1800 x 450mm. 5pcs of 30-cell egg tray molds can be mounted on each forming platen(5pcs/cycle).There are 40pcs of forming molds and 5pcs of transfer molds in total;

- Forming efficiency:20-21cycles/min;

- quip with vacuum auto drain system, preheating system, auto cleaning system for the forming mold and auto control cabinet.

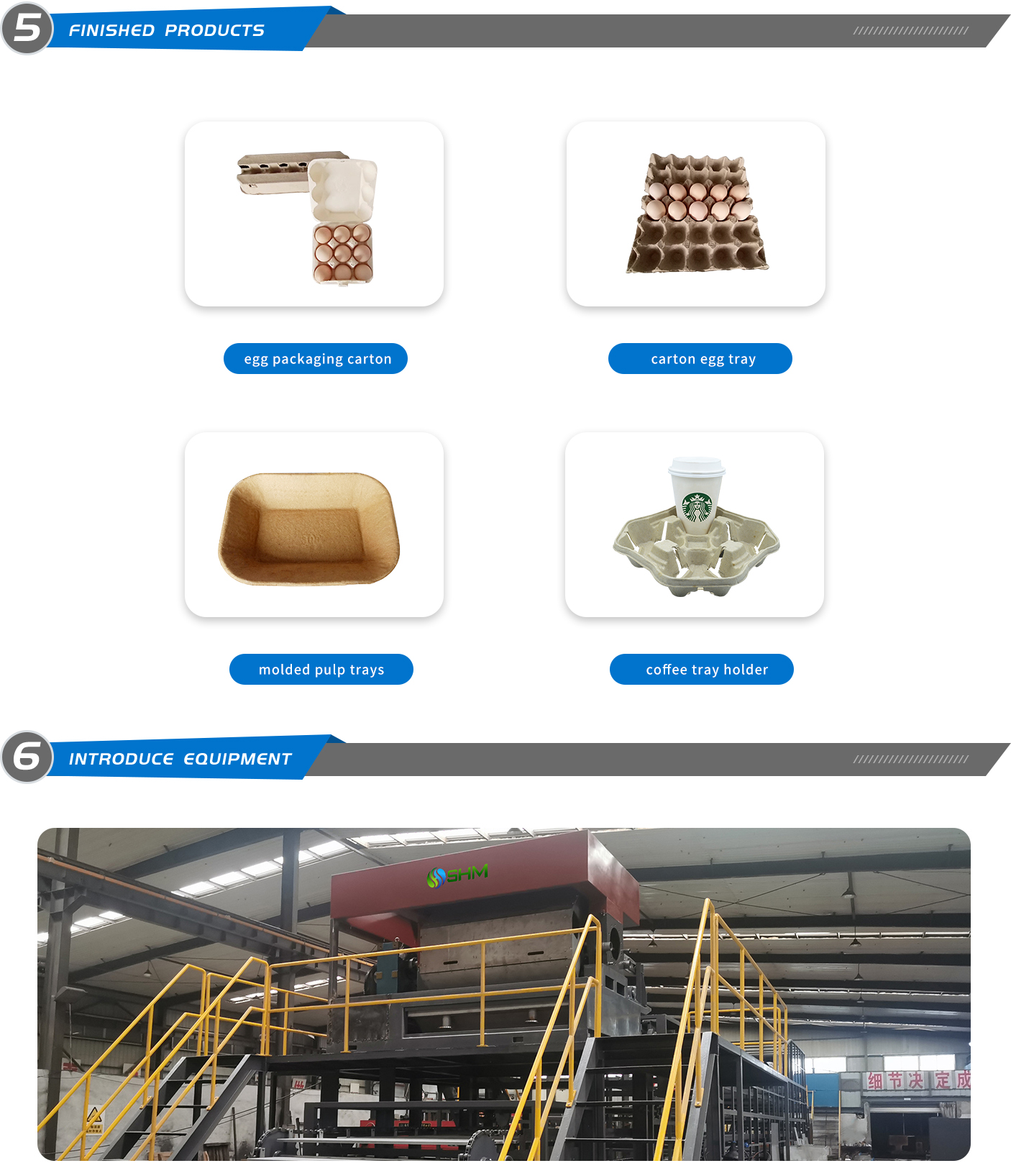

Sample pictures

From the same unit, you can also produce fruit trays for horticulture produce like apples, orange, etc, and also egg cartons or egg boxes. Egg Trays are often called filler trays and usually have 30 pockets i.e., they hold 30 eggs. Eggs are either sold uncovered in the tray or wrapped with plastic film.

Eggs come on market in boxes of different shapes and sizes and that can be designed for different egg number.

How do I start my own egg carton machine business?

SHM egg carton equipment is constructed with robust materials, ensuring durability and stable operation, which translates to minimal downtime and maintenance requirements.

Energy Efficiency: Energy-efficient design minimizes operational costs, promoting sustainability while remaining cost-effective.

Customization: SHM egg carton production line can be tailored to suit your specific requirements, including egg carton types, production capacity, and other unique features tailored to your needs.

Supplier Support: Count on SHM dedicated team for comprehensive training, technical support, and access to spare parts to guarantee your paper egg trays and boxes production line performs optimally.

Raw Materials for Egg Tray Machine

SHM egg tray making machine, from the primary raw materials used to the final whole production process, compared to plastic egg tray making machine, paper egg tray machine has carried out an environmentally friendly production process. Biodegradable materials are processed to make the egg trays hard enough and 100% biodegradable and recyclable. Basic raw materials are the paper waste. Paper pulp is soft material but pulp molded products viz trays being an integrated structure have suitable rigidity, good flexibility, and stiffness which makes it a suitable package for shockproof performance.

The waste paper can be old newspapers,100% carton, old books, old hard paper case, waste paper cup and so on. You can produce all colors of egg tray box, such as blue, pink, white, green, yellow and son on. It is a very interesting thing. SHM has egg carton tray machine for sale.

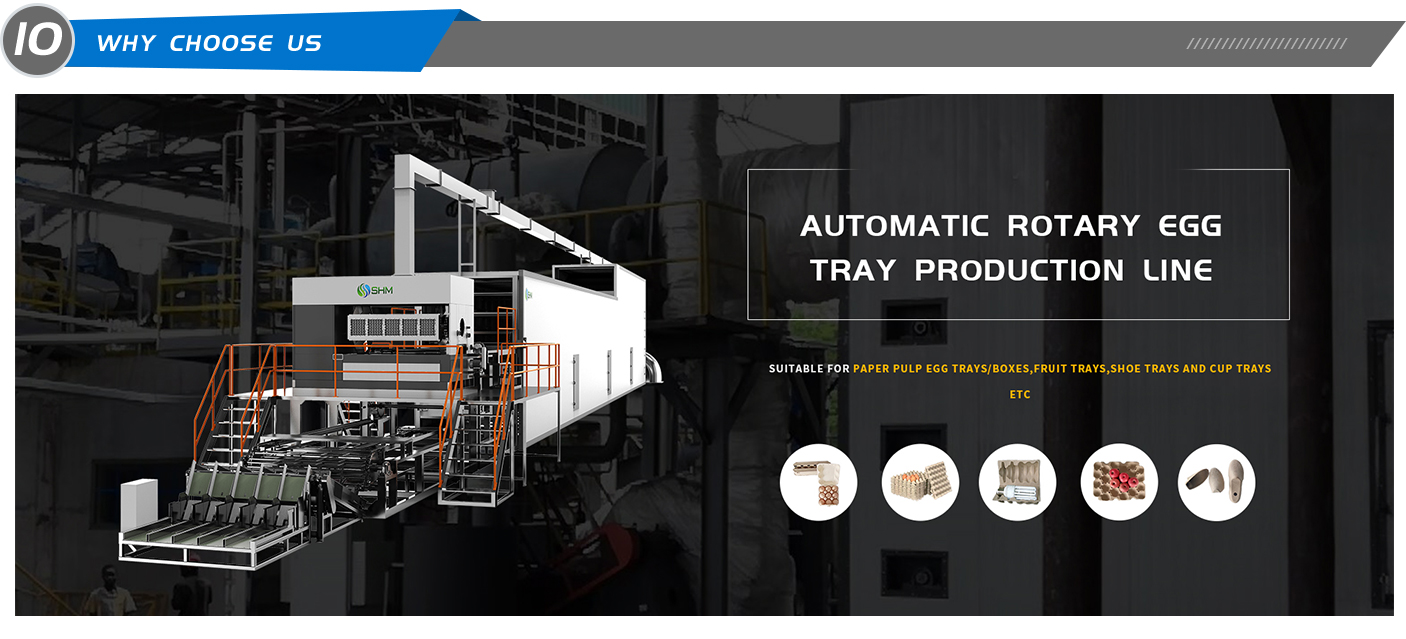

Why choose SHM?

SHM is a global supplier of high-quality molded fiber packaging production lines, we provide sustainable and innovative solutions for the food service and packaging market.

In 1989, the founder of the company Mr Chao started his work at pulp molding industry, and holds a number of pulp molding patents.

In 2007, SHM was established.

In 2014, SHM participated in the formulation of industry standards for pulp molding in China.

Automatic pulp molding equipment factory direct, SHM team pay great importance to quality;

Approvals from Top 5 USA packaging companies;

Have CE and ISO9001 certificates;

SHM owns 40+patents for fiber molded machines.

SERVICE

1. Engineering research and technical consultation;

2. Manufacture;

3. Project Schedule;

4. Preparation of documents and drawings;

5. Training of maintenance and operation personnel;

6. Guide Assembly line installation;

7. Electrical and mechanical design;

8. System integration;

9. System test and handover;

10. One year of after-sales support;

11. Spare parts are included;

12. Installation within the scope of supply;

13 Operation support for the buyer’s factory;

14. System test after equipment delivery;

15. Documentation of assemble line.

RELATED

RELATED