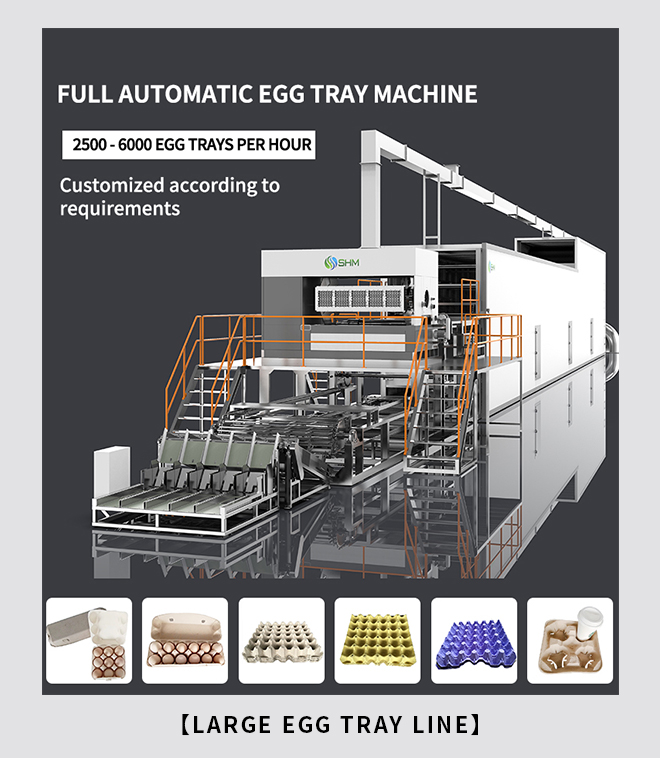

Fully Automatic Egg Tray Making Machine

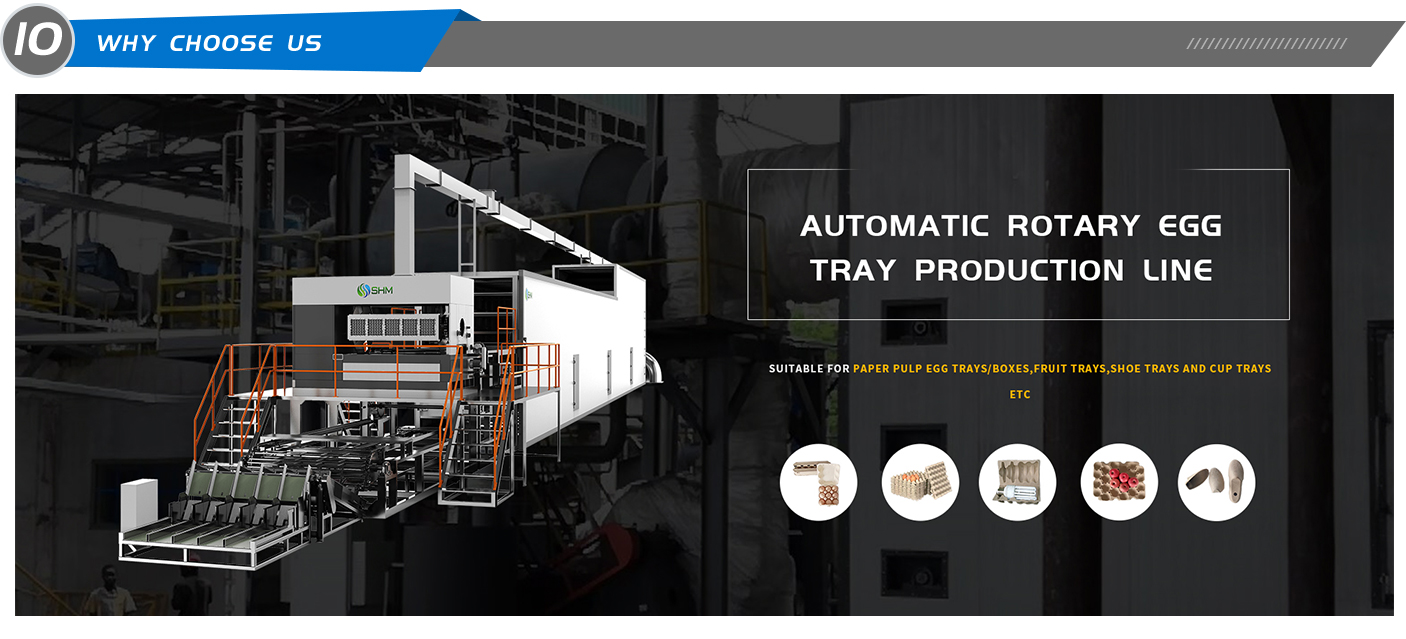

SHM is a factory that specializes in the production of pulp molding machinery, including egg tray machines, egg carton machines, and various other molded pulp packaging machines.

SHM egg carton maker, or an egg tray automatic machine, typically refers to a fully automatic egg tray making machine used for the production of egg cartons, egg trays, and similar molded pulp products.

Scope of supply:

1. Fully Automatic Egg Tray Making Machine: This machine automates the entire process of making egg cartons or trays from recycled paper pulp. It usually includes the following key steps:

Pulp Preparation: Waste paper or pulp material is mixed with water and additives to create a pulp slurry.

Molding: The slurry is transferred to molds designed for egg cartons or trays. The molds may use vacuum pressure to shape the pulp into the desired form.

Drying: The molded products are dried in the muti layer metal drying line, making them sturdy and ready for use.

2. Metal Drying Line: A metal drying line is an integral part of the production process. It consists of a series of metal trays or conveyor belts where the freshly molded egg cartons or trays are placed to dry. Heat is applied to evaporate the moisture content within the products, ensuring they are solid and rigid for packaging and use.

3. Automatic Stacking and Counting System: To optimize the production line, an automatic stacking and counting system is often employed. This system may include conveyor belts, robotic arms, or other mechanical components that stack the produced egg cartons or trays neatly and count them as they are stacked. This automation streamlines the packaging process and ensures efficiency and accuracy.

Related Parameters:

1.All bearings Japan NSK

2.Main electrical components Siemens

3.Burner Italian Riello

4.Drying line insulation layer 120kg/m3

5.Variable frequency circulation fan

6.The main engine is powered by a hydraulic mechanism

7.Equipped with fault overload protection device to prevent chain overload and breakage, resulting in maintenance difficulties and greater equipment damage.

8.Adjustable speed control system to help adjust the production speed.

- Power: 11KW;

- Power: 11KW;

- Consist of 8pcs of forming platens and 1 piece of transfer platen;

- Platen size: 1800 x 450mm. 5pcs of 30-cell egg tray molds can be mounted on each forming platen(5pcs/cycle).There are 40pcs of forming molds and 5pcs of transfer molds in total;

- Forming efficiency:20-21cycles/min;

- quip with vacuum auto drain system, preheating system, auto cleaning system for the forming mold and auto control cabinet.

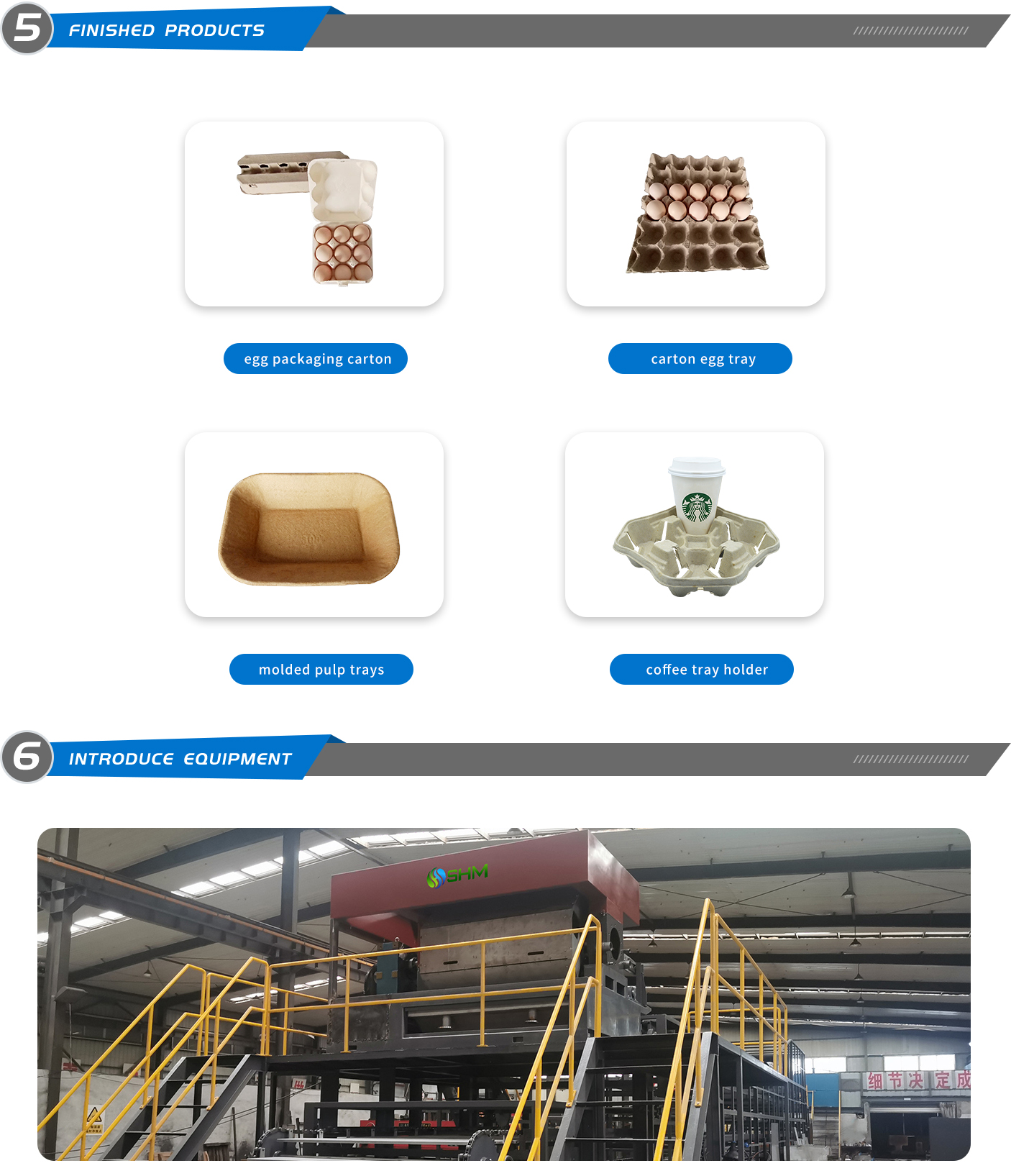

Sample pictures

From the same unit, you can also produce fruit trays for horticulture produce like apples, orange, etc, and also egg cartons or egg boxes. Egg Trays are often called filler trays and usually have 30 pockets i.e., they hold 30 eggs. Eggs are either sold uncovered in the tray or wrapped with plastic film.

Eggs come on market in boxes of different shapes and sizes and that can be designed for different egg number.

How do I start my own egg carton machine business?

By integrating a fully automatic egg tray making machine with a metal drying line and an automatic stacking and counting system, you can achieve high levels of production efficiency, product consistency, and reduced labor costs.

When choosing such a system for your specific needs, consider factors like production capacity, energy efficiency, customization options, and the quality of the end product. The exact features and capabilities can vary among manufacturers and models, so it's essential to select equipment that aligns with your production requirements.

Get a complete solution for your egg tray production line from SHM now, we will reply you in 24 hours.

Raw Materials for Egg Tray Machine

SHM egg tray making machine, from the primary raw materials used to the final whole production process, compared to plastic egg tray making machine, paper egg tray machine has carried out an environmentally friendly production process. Biodegradable materials are processed to make the egg trays hard enough and 100% biodegradable and recyclable. Basic raw materials are the paper waste. Paper pulp is soft material but pulp molded products viz trays being an integrated structure have suitable rigidity, good flexibility, and stiffness which makes it a suitable package for shockproof performance.

The waste paper can be old newspapers,100% carton, old books, old hard paper case, waste paper cup and so on. You can produce all colors of egg tray box, such as blue, pink, white, green, yellow and son on. It is a very interesting thing. SHM has egg carton tray machine for sale.

Why choose SHM?

SHM is a global supplier of high-quality molded fiber packaging production lines, we provide sustainable and innovative solutions for the food service and packaging market.

In 1989, the founder of the company Mr Chao started his work at pulp molding industry, and holds a number of pulp molding patents.

In 2007, SHM was established.

In 2014, SHM participated in the formulation of industry standards for pulp molding in China.

Automatic pulp molding equipment factory direct, SHM team pay great importance to quality;

Approvals from Top 5 USA packaging companies;

Have CE and ISO9001 certificates;

SHM owns 40+patents for fiber molded machines.

SERVICE

1. Engineering research and technical consultation;

2. Manufacture;

3. Project Schedule;

4. Preparation of documents and drawings;

5. Training of maintenance and operation personnel;

6. Guide Assembly line installation;

7. Electrical and mechanical design;

8. System integration;

9. System test and handover;

10. One year of after-sales support;

11. Spare parts are included;

12. Installation within the scope of supply;

13 Operation support for the buyer’s factory;

14. System test after equipment delivery;

15. Documentation of assemble line.

RELATED

RELATED

RELATED

RELATED