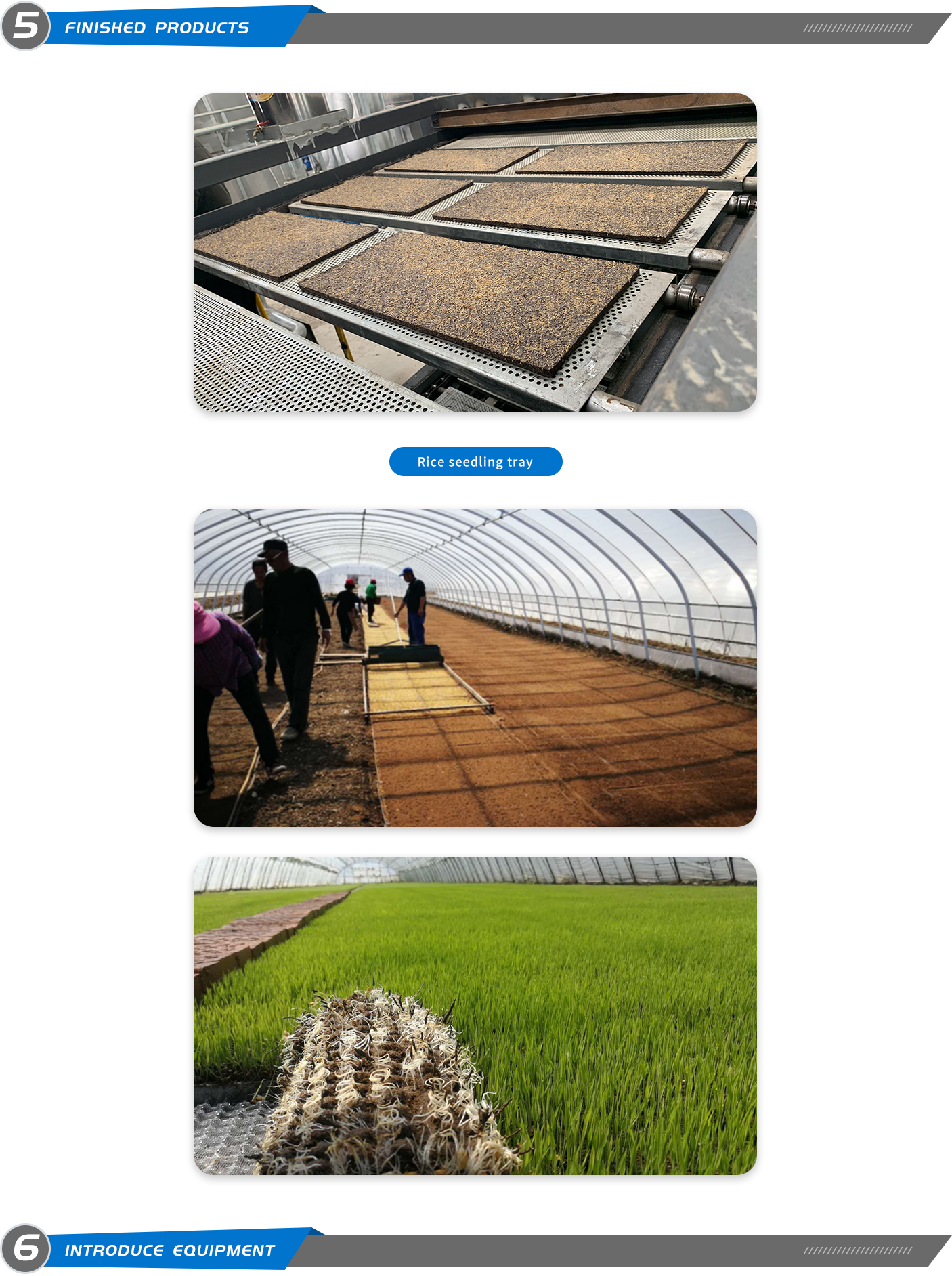

China Agricultural University has made significant progress in the research and treatment of agricultural wastes. They have successfully undertaken various research projects, including topics such as "diversity and synergistic mechanism of bacterial strains in straw lignocellulosic fast decomposing bacteria complex system," the "863 project," and the "research and development of new multi-functional bio-organic fertilizer." These projects have resulted in a series of achievements and demonstration projects in the utilization of agricultural waste for seedling matrix preparation and organic fertilizer production, these compostable and biodegradable finished products are good for rice nursery preparation .

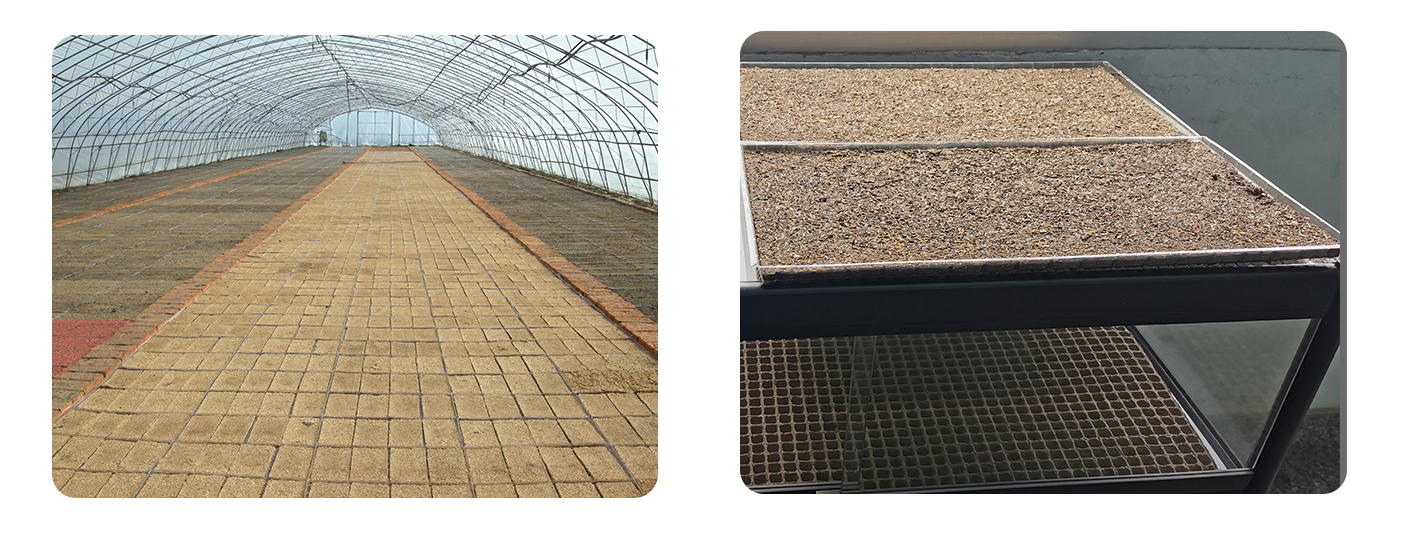

In collaboration with China Agricultural University, SHM has established a technical cooperation relationship focused on the development of rice seedling cultivation matrix plates. Through this partnership, CAU has shared expertise in matrix formula research, disease prevention formula research, and product manufacturing technology research. This collaborative effort represents an innovative breakthrough that has not been achieved by other institutions in China. As a result, SHM's advanced, leading, and competitive capabilities in this field are expected to endure for a significant period.

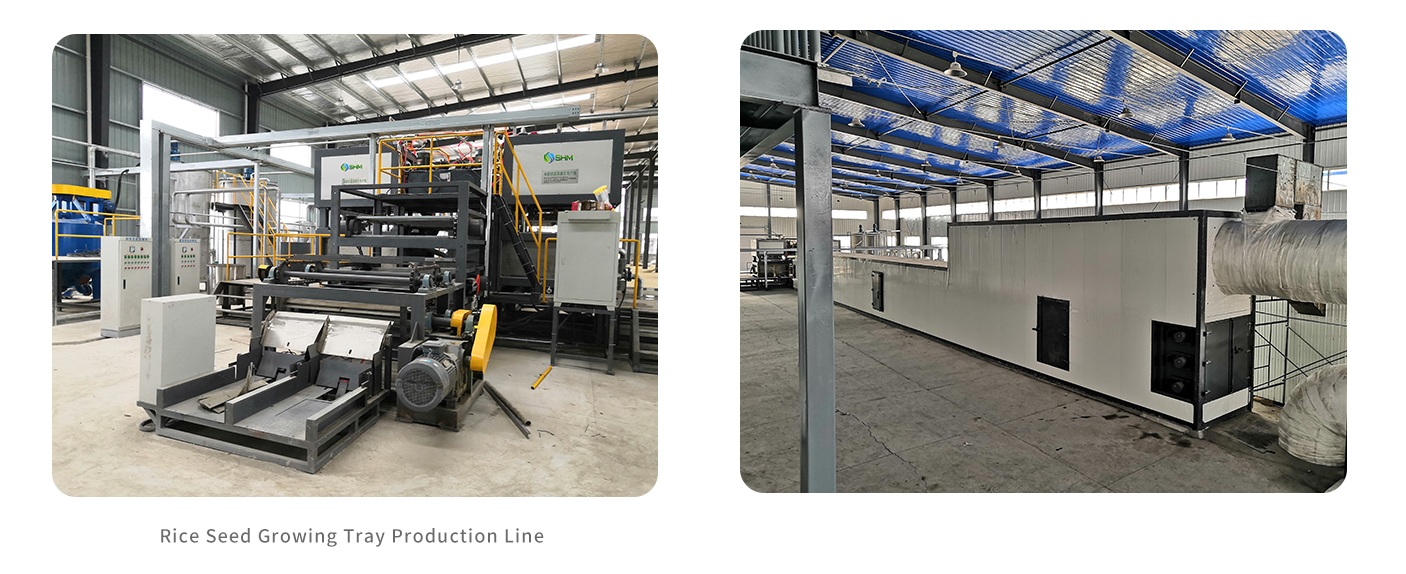

SHM is a global supplier of high-quality paddy nursery tray making machine production lines. With 30 years experience and excellent technical team, SHM provide sustainable and innovative solutions for the rice seedling tray market. Just feel free to send us an inquiry here, let's discuss the fiber solution that fits your brand and product!

Scientific research test platform

1. The integrated system has the characteristics of easy learning, easy use, easy maintenance and convenient installation, and can build a reliable and effective production / scientific research system in a short time.

2. It is applicable to customers who use the product for their own use, with less investment, low follow-up maintenance cost and large income. The integrated model does not need other infrastructure, such as slurry tank, plant, etc., which reduces other inputs of customers.

3. It is applicable to R & D projects, advanced control modes such as PLC control, color screen man-machine dialogue interface and touch operation. At the same time, it is also designed with manual control circuit design mode.

1. PLC control the forming machine with automatic high pressure cleaning mold device

2. All bearings in the production line adopt NSK brand bearings imported from Japan.

3. The sliding track uses ABB brand.

4. All electrical parts in the production line are based on the German Siemens brand.

5.Using the clean energy to dry products.

FACTORY CASE SHOW

In last year, we have set up two big capacity rice growing tray production line in China. Their capacity are 500 million pcs per year each one. This new molded pulp product is aimed at the large-scale excavation of cultivated layer soil for rice seedling cultivation, and the severe damage of the cultivated layer.

The agricultural and forestry wastes such as straw, mushroom fungus husk, rice husk, and biogas residue are rapidly matured through industrialization, giving a full set of nutrition, disease prevention, Weeding formula, made into a new brand-new "soilless seedling substrate". The "seedling substrate" can replace soil and is used for seedling and cultivation of rice and other crops. The project is of great significance for protecting cultivated soil, effectively using waste resources, improving crop planting methods, and reducing environmental pollution.

Why choose SHM?

SH Machinery has engaged in pulping molding filed since 1986.

Advantages includes:

Advantages includes:

1. 30 years technology accumulation for EU,USA PRODUCT manufacturers

2. Approvals from Top 10 USA packaging company

3. CE and ISO9001 certificate

4. OEM and ODM both accepted.

5. Own designing team for new products development

6. Quick delivery time for decent orders

7. 24 hours online sales/after sales services

Service Ability

1. Engineering research and technical consultation;

2. Manufacture;

3. Project Schedule;

4. Preparation of documents and drawings;

5. Training of maintenance and operation personnel;

6. Guide Assembly line installation;

7. Electrical and mechanical design;

8. System integration;

9. System test and handover;

10. One year of after-sales support;

11. Spare parts are included;

12. Installation within the scope of supply;

13 Operation support for the buyer’s factory;

14. System test after equipment delivery;

15. Documentation of assemble line.

RELATED

RELATED