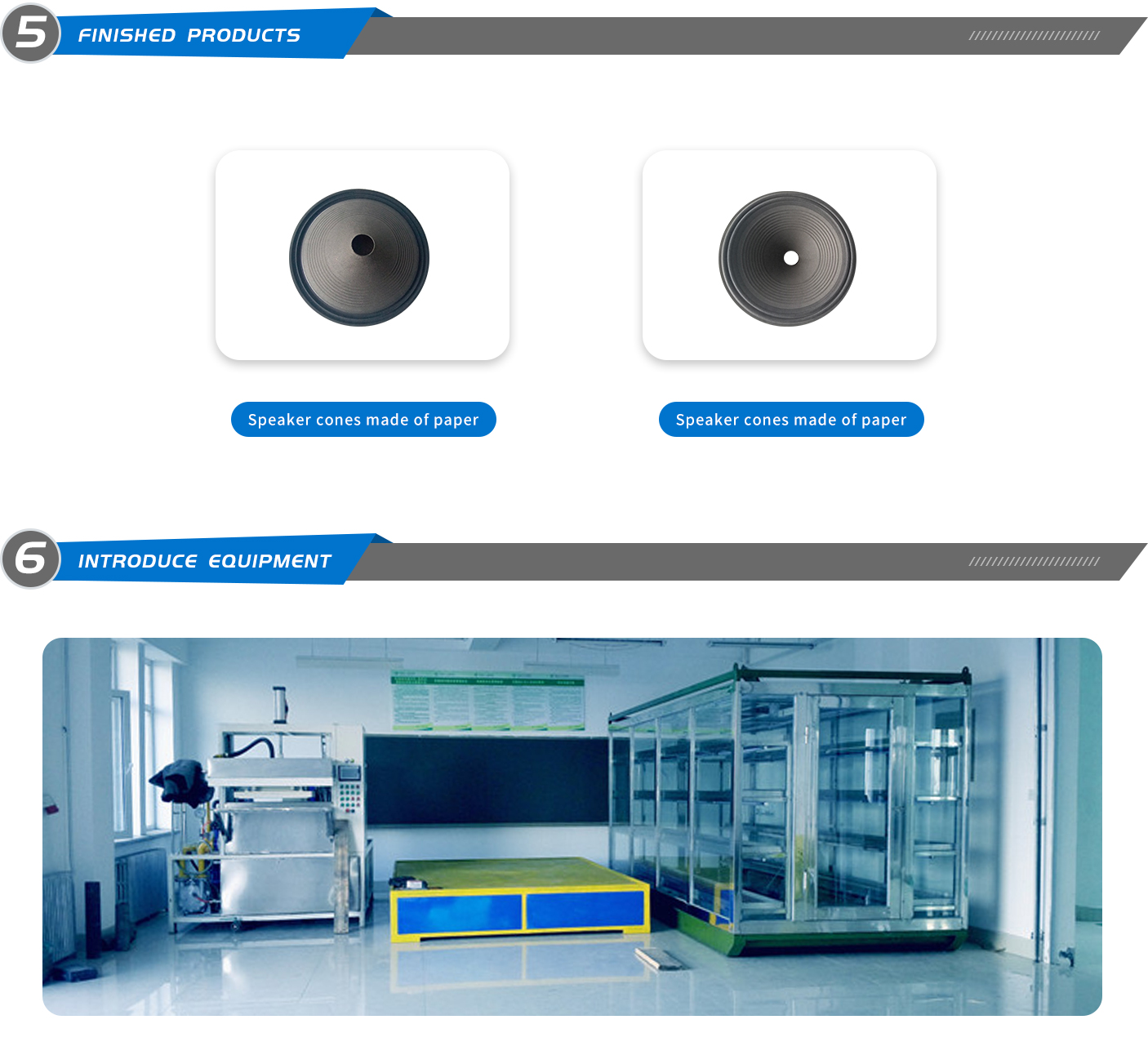

Paper Pulp Cone Fabrication:

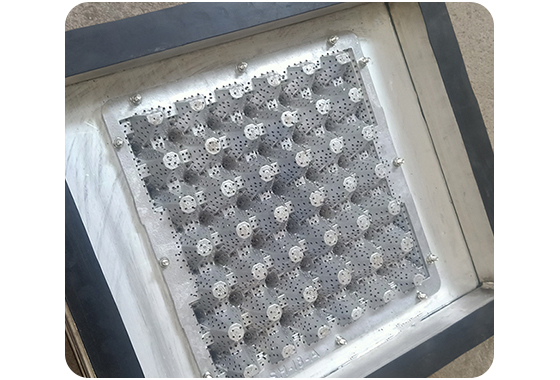

Loudspeaker cones are most commonly formed from paper pulp. Paper cone making machine process starts with sheets of various types of pulp. The pulp recipes, additives, pulp slurry beating process, and cone forming techniques all contribute to the loudspeaker cone’s characteristics. Paper cone production from pulp slurry mixing to cone forming.

Paper cone production from pulp slurry mixing to cone forming, hot pressing and at last edge trimming.pulp speaker cone making machine is a integrated manufacturing equipment, recipe provided by customer.

Pulp molding machine assembly instructions:

1.Forming machine

2.Hydrapulper

3.Air Compressor

4.Air compressor storage tank

5.Agitator

6.Control cabinet

7.Pulp pump

8.Pulp pool

9.Water pool

10.Vacuum pump

11. Receiving table

12. Metal stairs

13. Hot-pressing machine(optional)

14. Edge trimming machine(optional)

15. Metal drying line(optional)

1.Normal model:SHW-360A, machine size: 4100X2100X2700mm,SHW-360B, machine size: 2900X1800X2000mm,Platen size: Customized,Mould size: Customized

2.Minimum number of units: up to your product size

3.Forming efficiency: 0-4 times/minute

4.Production line overall dimension: length≥4m,width≥2m, the finished products room must be greater or equal to 100m²

5. Production line total power: 18kw-28kw. Actual total energy power consumption by 70%.

6. This production line is configured as standard, if it is used to produce egg cartons recyclable,fruit and vegetable display trays, disposable coffee tray, bagasse pulp plate etc, it needs auxiliary equipment, like hot press machine, edge trimming machine, or printing machine etc. Corresponding area, total power, worker quantity will be increased.

7. The water is recycled, it needs to be changed when it recycled several times.

8. SHM is in charge of installation, debugging and training,and we also provide a one-year warranty service after installation.

Small sized production pulp molding machine features:

- Stainless steel stock container

- Robust stainless steel construction

- Built-in air compressor and reservoir

- Customized-shape mold

- Compact, easy to install and user friendly

- Manual heat press

With the objectives of identifying important variables in the molded pulp process, pulps and white water samples from an industrial pulp and paper mill were analyzed at the laboratory scale. The laboratory trials were carried out using a factorial design. The laboratory trays represent well the behaviour of the industrial trays. Also, the suspended solids of white water at laboratory reproduce the quality of industrial water correctly. Finally, the establishment of reference values for the raw material quality indices is an interesting technique for those mills that use recycled paper. So more and more colleges purchasing this kind of small pulp molding machine for their lab.

Please feel free to send us an inquiry if you want to consult this kind of Small Laboratory Pulp Molding Machine. You can get this kind of small paper pulp molding machine by online from Shuanghuan.

1.Metal drying line/Shelf: since the product quantity is small, you can just let them dry on the shelf, more cost-effective than metal drying line.

2.Hot pressing machine pulp: for shaping the products, like food containers, cell phone trays.

3.Edge trimming machine: make the edge smoothly.

Make paper egg tray raw material: cardboard,newspapers notebooks, magazines, A4 paper,used egg trays, recycled paper products.

Custom industrial molded pulp packaging:Bagasse pulp sheet, straw pulp sheet, bamboo pulp sheet etc.

Why choose SHM?

SH Machinery has engaged in pulping molding filed since 1986.

Advantages includes:

Advantages includes:

1. 30 years technology accumulation for EU,USA PRODUCT manufacturers

2. Approvals from Top 10 USA packaging company

3. CE and ISO9001 certificate

4. OEM and ODM both accepted.

5. Own designing team for new products development

6. Quick delivery time for decent orders

7. 24 hours online sales/after sales services

SERVICE

1. Engineering research and technical consultation;

2. Manufacture;

3. Project Schedule;

4. Preparation of documents and drawings;

5. Training of maintenance and operation personnel;

6. Guide Assembly line installation;

7. Electrical and mechanical design;

8. System integration;

9. System test and handover;

10. One year of after-sales support;

11. Spare parts are included;

12. Installation within the scope of supply;

13 Operation support for the buyer’s factory;

14. System test after equipment delivery;

15. Documentation of assemble line.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED