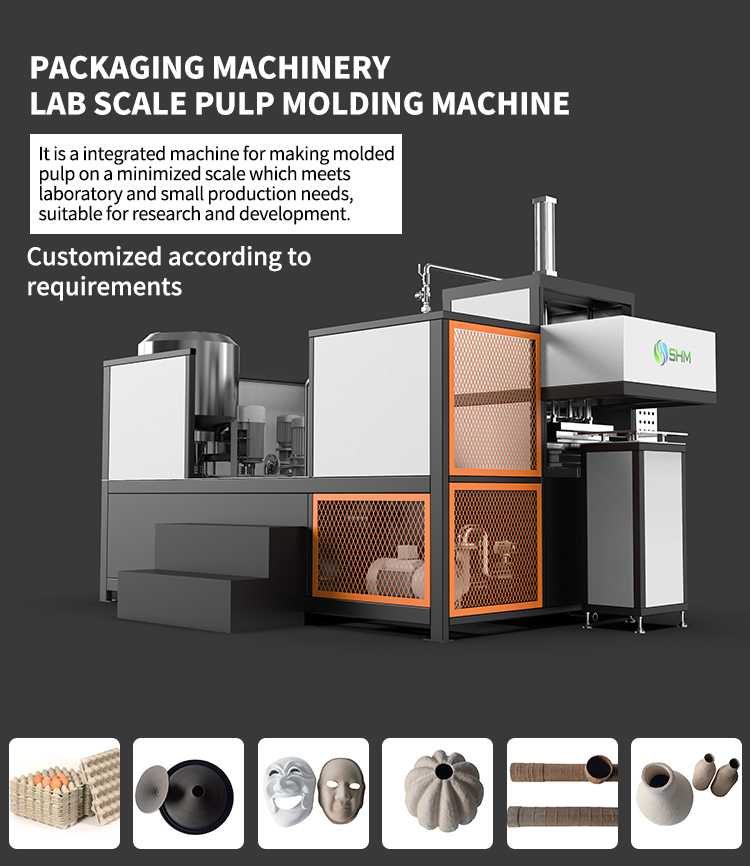

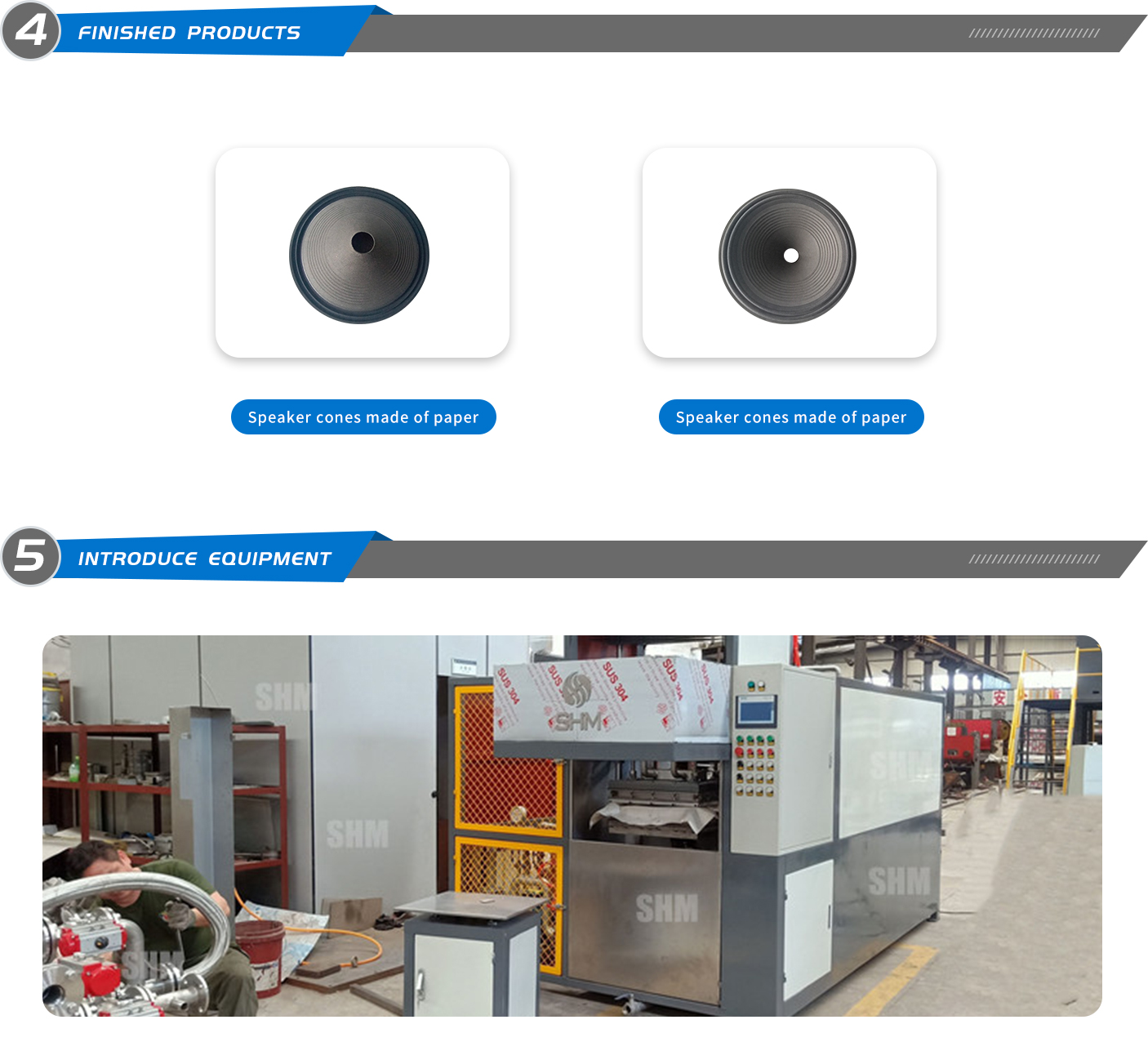

The speaker paper cone making machine is an advanced solution for manufacturing high-quality speaker cones with precision and efficiency. This automated system utilizes pulp molding technology to transform paper or other composite materials into speaker cones of varying sizes and specifications. With a focus on accuracy and consistency, the paper speaker machine ensures uniform production, meeting the stringent standards of the audio industry. From shaping to drying, the entire process is streamlined for optimal performance. This machinery caters to the demand for reliable and customizable speaker cone production, making it an essential component for businesses in the audio manufacturing sector seeking precision and efficiency in their operations.

1. Paper speaker cones are taken out by mechanical arms and put them on platform automatically. It reduces the intensity of labors.

2. Apply PLC control, touch screen operate with safely, stable and easy operating.

3. All equipment are put on one platform, space saving, easy to installation and transportation.

4. Small size and small capacity, suitable for small batch production and pulp molding product development.

5. Customizable Molds: The machine may offer customizable molds, allowing you to create trays and boxes with various shapes, sizes, and compartment configurations.

SHM speaker cone making machines offer a comprehensive solution for your paper speaker production needs. They streamline the manufacturing process, reduce waste, and maintain the quality of your speaker cones while minimizing environmental impact.

SHM is a global supplier of high-quality molded fiber packaging production lines, we provide sustainable and innovative solutions for the food service and packaging market.

In 1989, the founder of the company Mr Chao started his work at pulp molding industry, and holds a number of pulp molding patents.

In 2007, SHM was established;

In 2014, SHM participated in the formulation of industry standards for pulp molding in China;

SHM team pay great importance to quality, automatic pulp molding equipment factory direct;

Owns CE and ISO9001 certificates;

13+ years high-tech enterprises in China;

15+ years Alibaba member;

SHM owns 40+patents for fiber molded machines;

Approvals from Top 5 USA packaging companies.

SERVICE

1. Engineering research and technical consultation;

2. Manufacture;

3. Project Schedule;

4. Preparation of documents and drawings;

5. Training of maintenance and operation personnel;

6. Guide Assembly line installation;

7. Electrical and mechanical design;

8. System integration;

9. System test and handover;

10. One year of after-sales support;

11. Spare parts are included;

12. Installation within the scope of supply;

13 Operation support for the buyer’s factory;

14. System test after equipment delivery;

15. Documentation of assemble line.

RELATED

RELATED

RELATED

RELATED