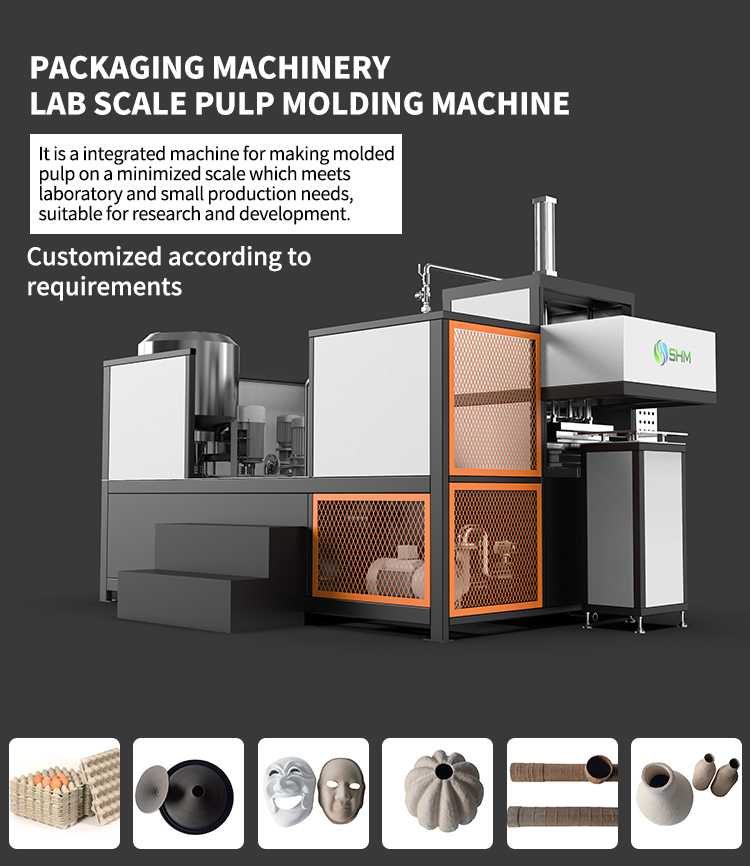

SHM male urinal bottle machines, also called plant fiber pulp molding production line is an innovative solution designed for the eco-friendly and efficient production of male urinal bottles. This production line incorporates advanced features, including a metal dryer, to ensure high-quality output and a fully automated, environmentally friendly production process.

Raw Material Utilization:

Pulp urinal machine processes a variety of waste paper materials such as old newspapers, magazines, books, other plant fiber, etc.

Utilizes easily accessible and sustainable raw materials, contributing to waste reduction and environmental conservation.

Fully-Automatic Control:

Operates with a fully-automatic control system for seamless and efficient production.

Automated processes from raw material input to final product formation, reducing the need for manual intervention.

Equipment Quality Standard Compliance:

Adheres to the highest quality standards, SHM has certified with the CE mark.

Stringent quality control measures at every stage of production ensure consistently high-quality male urinal bottles.

Metal Dryer Technology:

Incorporates a metal dryer in the production line for efficient and rapid drying of molded urinal bottles.

Enhances production speed and ensures a thoroughly dried end product, meeting hygiene standards.

SERVICE

1. Engineering research and technical consultation;

2. Manufacture;

3. Project Schedule;

4. Preparation of documents and drawings;

5. Training of maintenance and operation personnel;

6. Guide Assembly line installation;

7. Electrical and mechanical design;

8. System integration;

9. System test and handover;

10. One year of after-sales support;

11. Spare parts are included;

12. Installation within the scope of supply;

13 Operation support for the buyer’s factory;

14. System test after equipment delivery;

15. Documentation of assemble line.