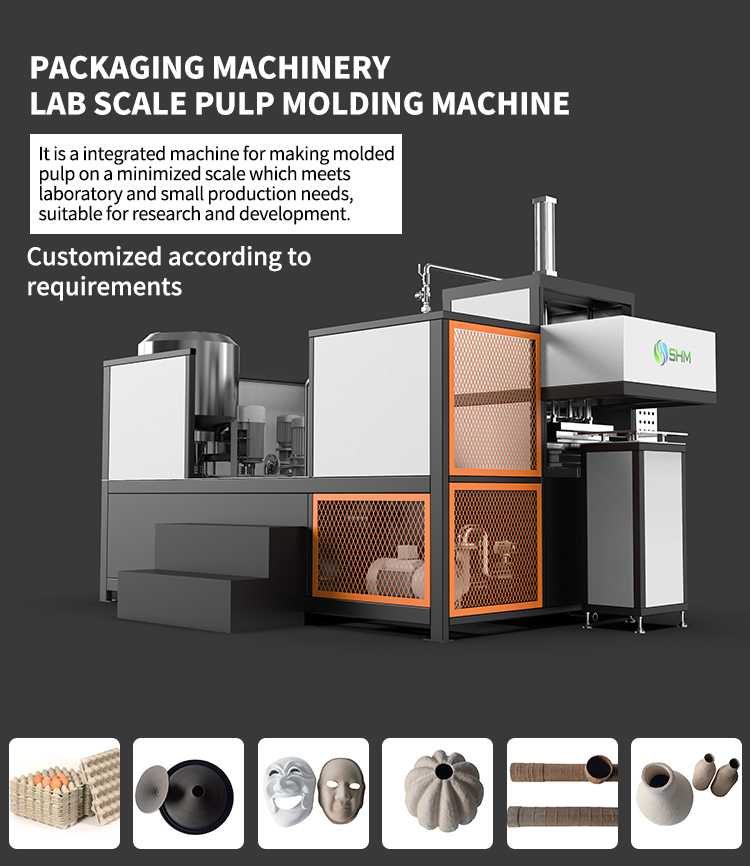

The SHM Pulp Urinal Bottle Production Line is an advanced and efficient solution for the manufacturing of medical pulp urinal bottles and trays. Specifically designed for medical facilities and healthcare institutions, this medical pulp molded tray machinery ensures the production of high-quality, hygienic, and eco-friendly medical pulp products.

The medical pulp molded tray machinery is designed with a user-friendly interface, allowing for easy operation and monitoring of the production process, quantity from small to large scale.

Automated pulp molding, drying, and shaping processes reduce manual intervention, enhancing overall productivity.

Raw Material Utilization:

Pulp urinal machine processes a variety of waste paper materials such as old newspapers, magazines, books, other plant fiber, etc.

Utilizes easily accessible and sustainable raw materials, contributing to waste reduction and environmental conservation.

Fully-Automatic Control:

Operates with a fully-automatic control system for seamless and efficient production.

Automated processes from raw material input to final product formation, reducing the need for manual intervention.

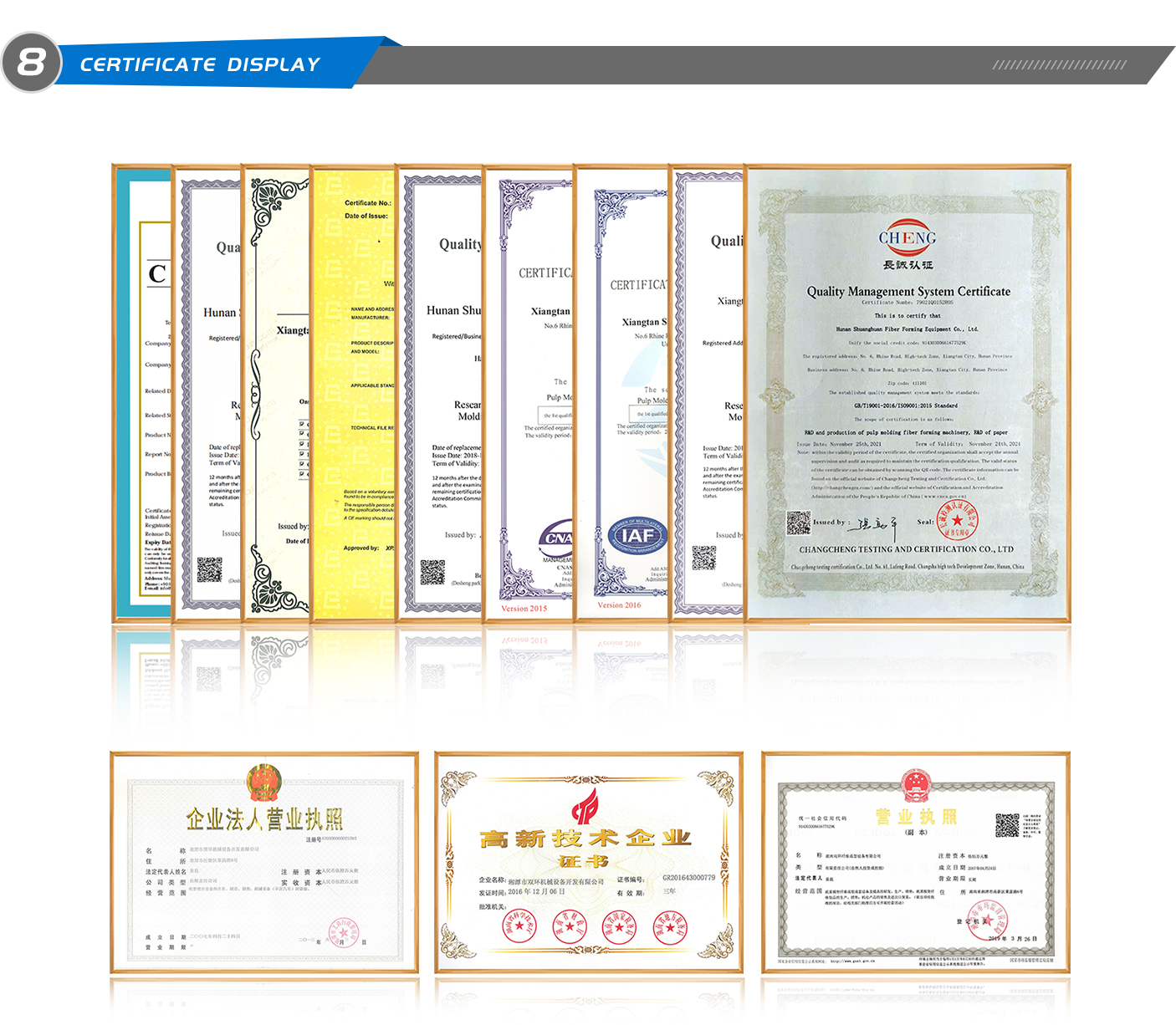

Equipment Quality Standard Compliance:

Adheres to the highest quality standards, SHM has certified with the CE mark.

Stringent quality control measures at every stage of production ensure consistently high-quality male urinal bottles.

Metal Dryer Technology:

Incorporates a metal dryer in the production line for efficient and rapid drying of molded urinal bottles.

Enhances production speed and ensures a thoroughly dried end product, meeting hygiene standards.

SERVICE

1. Engineering research and technical consultation;

2. Manufacture;

3. Project Schedule;

4. Preparation of documents and drawings;

5. Training of maintenance and operation personnel;

6. Guide Assembly line installation;

7. Electrical and mechanical design;

8. System integration;

9. System test and handover;

10. One year of after-sales support;

11. Spare parts are included;

12. Installation within the scope of supply;

13 Operation support for the buyer’s factory;

14. System test after equipment delivery;

15. Documentation of assemble line.