pulp moulding machinery product is a three-dimensional paper-based product that uses recycled pulp such as waste paper as the main raw material, adopts a unique process and related additives in the papermaking industry, and is pressed on a special mesh mold to form a three-dimensional paper-based product. Pulp moldings are also called paper molds or paper trays. Pulp molded products are mainly used in the transportation buffer protection of eggs and small electronics, and can also be made into beverage cup holders, medical utensils, disposable flower pots, etc. In the whole production process of pulp molding products, an indispensable tool is the mold, and the molds used in different processes of the paper mold are also different, and the following three sets of molds may be required: suction molding, heat Compression molding die, positioning trimming die. The latter two molds depend on the requirements of the product, but the suction molding mold is an indispensable mold in the production process.

Generally, for the production of industrial paper molds, the following three molds may be used: suction molding molds, hot-pressing molding molds, and trimming molds. The use of these three molds depends on the production process. The latter two molds are only required when shaping and trimming are required; however, the suction molding mold is an indispensable one in the production process of paper molds. .

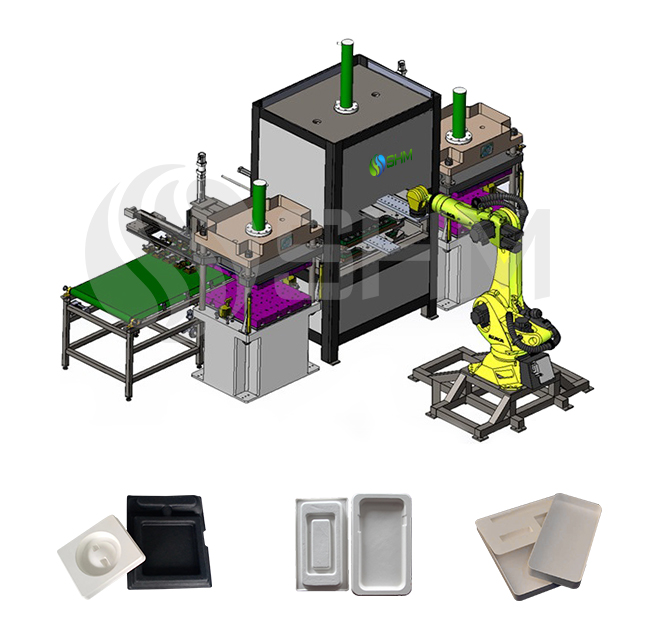

1. Suction molding die

Mainly, the pulp is formed into a wet paper mold, which is generally divided into two parts, an upper mold and a lower mold, and the function of suction molding is completed by the work of the molding machine equipped with the upper and lower molds.

2. Hot pressing shaping model

The hot-pressing molding die includes two parts: the hot-pressing molding upper mold and the hot-pressing molding lower mold. The most commonly used cast aluminum material is the material of the hot-pressing molding die. Cast aluminum has excellent casting properties, easy processability and good thermal conductivity, making it a better material for hot pressing molding.

3. Positioning the trimming die

The positioning trimming die is mainly used to make the four sides of the paper mold flush and regular, and it is needed when the paper mold needs to be trimmed. The paper die trimming die can be installed on hydraulic presses, crank presses and air presses.